Xingaonai

Xingaonai

Aluminum is a metal element with physical properties such as low density, good electrical conductivity and thermal conductivity, as well as chemical properties such as corrosion resistance, non-flammability and recyclability. It is widely used in industries such as automobiles, aircraft, electronics, construction, and decoration. So, where does aluminum come from? How is aluminum made? How to make aluminum? With these questions, New High Heavy Industry will explain in detail.

Aluminum mainly comes from bauxite. Aluminum is finally obtained through a series of process operations such as mining bauxite, producing alumina, and electrolytic aluminum production.

Mining of bauxite

Bauxite is the main raw material for preparing aluminum, and the mining process must strictly comply with environmental protection and safety requirements. Under normal circumstances, bauxite is mined in open-pit mining and underground mining. Open-pit mining is used for shallow ore bodies, and underground mining is used for deeper ore bodies. Underground mining requires more manpower and material resources. The mined bauxite needs to be pre-treated by crushing and screening to ensure that the particle size and composition of the ore meet the subsequent process requirements.

Extracting Alumina

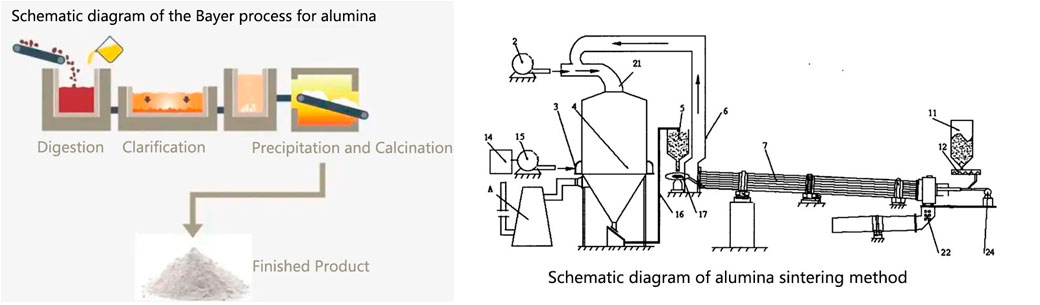

Extracting alumina is a key step in the preparation of aluminum. First, bauxite is processed by the Bayer process or sintering process to dissolve the alumina in it. Subsequently, the alumina is separated from the solution through filtration, precipitation and other processes to obtain pure alumina powder.

Preparing aluminum by electrolysis

After obtaining the alumina powder, it is reduced to metallic aluminum by electrolysis. In this process, the alumina is dissolved in molten cryolite as an electrolyte. Through the action of direct current, the alumina in the electrolytic cell is reduced to metallic aluminum and deposited on the cathode of the electrolytic cell.

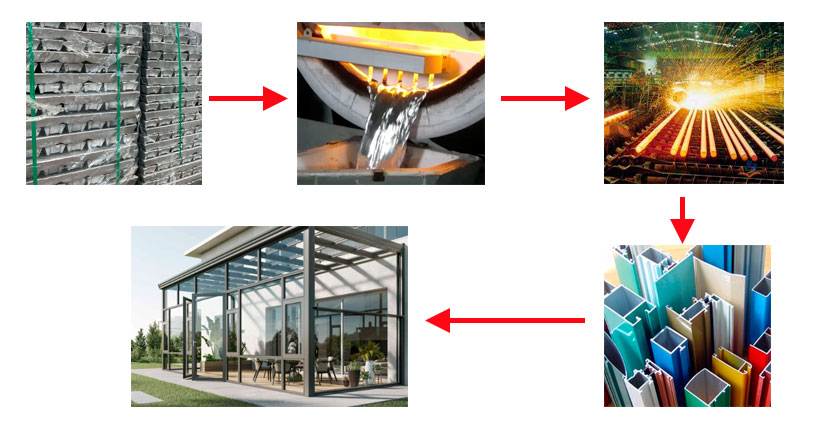

Refining and processing of aluminum

Metallic aluminum prepared by electrolysis also contains certain impurities, so it needs to be refined. During the refining process, the composition of aluminum is adjusted by adding certain alloying elements to improve its mechanical properties and corrosion resistance. Finally, aluminum is processed into aluminum materials of various specifications and shapes through rolling, stretching and other processing processes.

Aluminum is a material with excellent recyclability, and its recycling process is simple and efficient. Scrap aluminum can be converted into new aluminum ingots after remelting. The energy consumed in this recycling process only accounts for 5% of the energy consumed in the production of original aluminum. Aluminum recycling not only helps save resources, but is also a key link in reducing environmental pollution and promoting sustainable development.

Article Title: Where does aluminum come from? How is aluminum made? Aluminum recycling

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Where-does-aluminum-come-from-How-is-aluminum-made-Aluminum-recycling.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap