Xingaonai

Xingaonai

As a common building material, concrete refers to the general term for engineering composite materials in which aggregates are bonded into a whole by cementitious materials. Generally speaking, concrete refers to cement as a cementitious material and sandstone as an aggregate, which is made of water, cement, admixtures, etc. in a certain proportion.

Impact crusher is a common mining crushing equipment. With its unique working principle and excellent performance, it plays an important role in mining, construction, transportation and other fields. It is suitable for the crushing of medium hardness and brittle materials, and has the characteristics of high efficiency and energy saving, large crushing ratio, good particle shape and wide adaptability.

Whether concrete needs to be crushed depends on the application scenario and processing requirements. For concrete that needs to be crushed and reshaped, impact crushing technology is an effective treatment method. In practical applications, concrete is sometimes required to be crushed to meet different construction requirements. So, what role does the impact crusher play in concrete production? With doubts, Xin Gaonai Heavy Industry explains in detail.

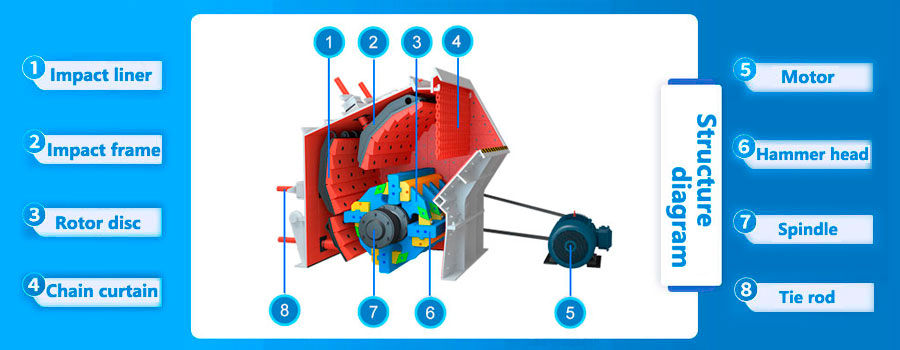

The impact crusher is mainly composed of a feed port, a rotor, an impact plate, an adjustment device, a discharge port, a motor, etc. The working principle is that the motor drives the rotor to rotate at high speed through the transmission device, and the rotor drives the impact plate to impact and crush the material. After the material enters the crushing chamber, it is crushed by the hammer on the high-speed rotating rotor, and then crushed again by the impact plate, and finally discharged from the discharge port. In this process, the material collides and rubs multiple times between the hammer and the impact plate, thereby achieving the crushing effect.

1. High efficiency and energy saving: In the combination of the impact plate and the high-speed rotating rotor, not only the crushing efficiency is high, but also the energy consumption can be reduced. At the same time, it is also equipped with a cooling heat dissipation system, which can dissipate the heat generated during the crushing process in time to ensure the stable operation of the machine.

2. Large crushing ratio: The material can be crushed to the required particle size at one time, reducing the input and energy consumption of secondary crushing.

3. Strong adaptability: It can crush materials of various hardness, such as granite, limestone, basalt, etc. In addition, by adjusting the gap between the impact plate and the rotor, different particle size requirements can be crushed.

4. Uniform particle size: The crushed material is not only uniform in particle size, but also in a cubic shape, which effectively reduces the input cost and improves the utilization rate of the material.

5. Easy maintenance: simple design, compact structure, easy disassembly and maintenance. At the same time, the equipment is equipped with a complete lubrication system and safety protection devices to ensure the safe and reliable operation of the equipment.

PF series impact crusher

PF impact crusher is suitable for various rock materials with particle size ≤500mm and compressive strength ≤350MPa. It is generally used in the crushing of stones with high hardness such as bluestone, limestone, shale, etc.

Features of PF impact crusher: The whole machine has good particle shape, uniform particle size, more crushing and less grinding stone powder content. The gap between the impact plate and the hammer can be adjusted to control the particle size of the equipment. The wear resistance of the wearing parts is poor, but it can still meet the basic operation, and the price is low and the cost performance is high.

HD German version impact crusher

It adopts a new manufacturing technology and has been upgraded in structural design, which greatly improves the wear resistance of the equipment. Only 6 plate hammers are installed on the rotor of this crusher, which makes installation and replacement easier and more convenient.

Features of HD German version impact crusher: The whole plate structure makes the discharge more small-sized and cubic, with excellent material shape and no internal lines. The hydraulic power-assisted design makes it easier to adjust the discharge port and plays an overload protection role. The plate hammer is made of high-wear-resistant material, its life is very long, and the back and sides are not easy to be worn

CI series impact crusher

CI impact crusher is a new type of impact crusher. The rotor and crushing cavity are refined for different applications. A large number of new high-wear-resistant materials are used to improve the performance and processing capacity of the equipment, while extending the service life of the equipment and reducing the failure rate.

Features of CI series impact crusher: The rotor and cavity are refined, and the speed and power are reasonably matched to meet the different crushing requirements of coarse, medium and fine. There are 3 impact plate racks, all of which adopt spring buffer structure. The material is repeatedly impacted and crushed, with better particle shape and uniform particle size. Two sets of identical hydraulic cover opening devices are installed on both sides of the frame, which can easily open and close the upper cover to adjust the discharge particle size or perform maintenance.

Article Title: What are the types of impact crushers in concrete production?

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/What-are-the-types-of-impact-crushers-in-concrete-production.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap