Xingaonai

Xingaonai

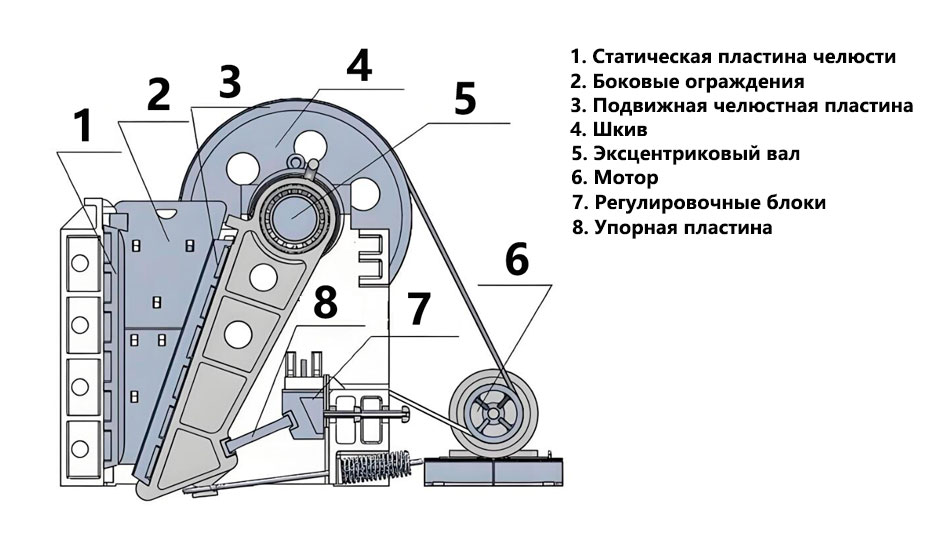

Jaw crusher is a commonly used crushing equipment, widely used in the crushing of various ores and bulk materials in mining and smelting, building materials, highways, railways, water conservancy and chemical industries. It consists of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side guard plate, a toggle plate, a toggle plate back seat, a gap adjustment screw, a reset spring, a fixed jaw plate and a movable jaw plate. The jaw crusher developed by Xingaonai based on the specific industrial and mining conditions of the domestic sand and gravel industry has the characteristics of large crushing ratio, high output, uniform product particle size, simple structure, reliable operation, convenient maintenance, and economical operating costs.

Before adjusting the gap, the following preparations need to be made: 1. Confirm that the machine is in shutdown state, and the power and gas are cut off; 2. Install the protective cover and safety protection equipment to ensure the safety of personnel; 3. Prepare tools, including reflectors, rulers, screwdrivers, camshafts, manual oil pumps, induction rulers, etc.; 4. Confirm the location of the gap adjustment.

(1) Adjust the gap of the lower shell: remove the screws of the lower shell, turn the lower shell over, and place the inspection roller inside it; use a reflector to check the roller gap, adjust the base screws, and the initial adjustment range is generally 0.1-0.3mm, which is adjusted according to the manufacturer's requirements; after the adjustment is completed, use an induction ruler to measure whether the roller gap meets the requirements.

(2) Adjust the gap of the upper shell: remove the screws of the upper shell, turn the upper shell over, and place the inspection roller inside it; use a reflector to check the roller gap, adjust the base screws, and the initial adjustment range is generally 0.05-0.15mm, which is adjusted according to the manufacturer's requirements; after the adjustment is completed, use an induction ruler to measure whether the roller gap meets the requirements.

Pay attention to safety when adjusting the gap and make sure that the equipment has stopped running; the equipment must be checked before adjustment to ensure that it can work normally; the size of the gap has a great influence on the crushing effect of the equipment and cannot be adjusted at will; after the adjustment is completed, the equipment must be tested to ensure that the adjustment is correct; check the gap regularly to maintain the normal operation of the equipment.

The above is the gap adjustment method and precautions of jaw crusher described by Xin Gaonai Heavy Industry. If you want to better use and maintain the jaw crusher equipment, you need to continuously perform maintenance and repair work. Adjusting the gap is one of the important steps, and you need to regularly check the equipment to ensure that the equipment is in the best working condition, so as to bring greater benefits to production.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/749.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap