Case Introduction

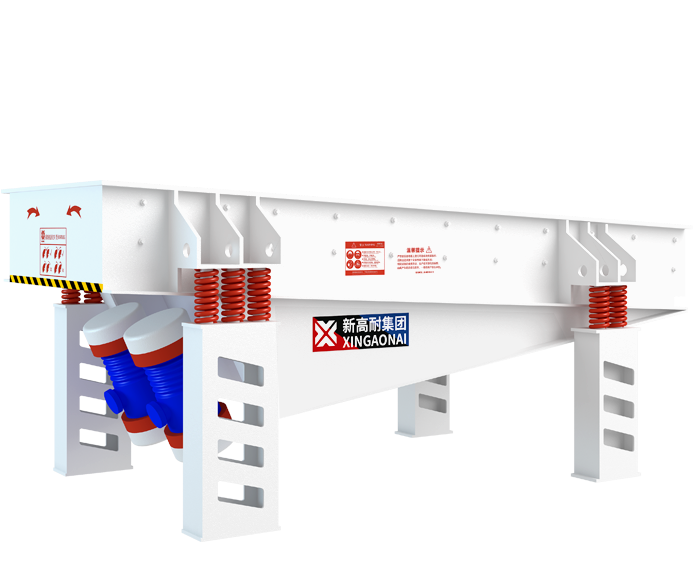

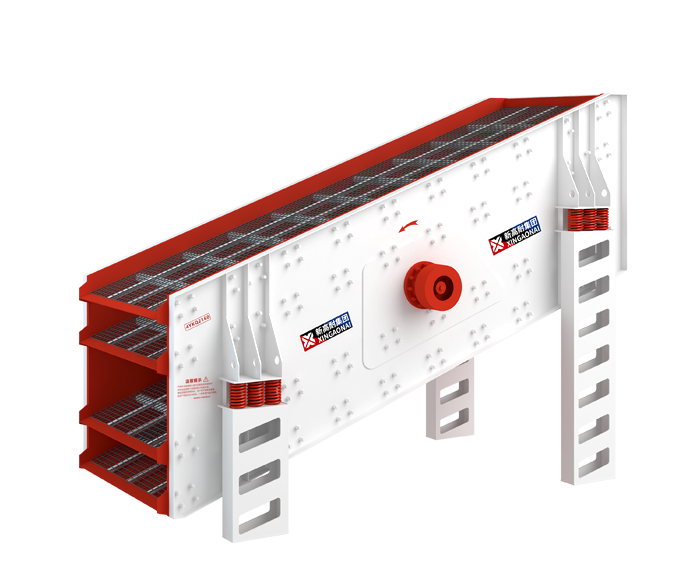

The gravel processing plant uses limestone as the raw material for crushing. The production line is configured in combination with the terrain of the region, user needs and the characteristics of the limestone raw materials. The operation efficiency is higher. The simple production line process is as follows: 1. First crushing: large pieces of limestone are evenly fed into the heavy hammer crusher through a vibrating feeder for preliminary crushing. 2. Second crushing: the limestone after preliminary crushing is sent to the light hammer crusher for secondary medium and fine crushing. 3. Screening: After reasonable screening by the vibrating screen, unqualified stones are returned to the light hammer crusher for re-crushing. After screening by the vibrating screen, qualified stones with moderate particle size are sent to the finished product pile to obtain machine-made sand and gravel with uniform texture and different particle sizes.

Related configuration