Case Introduction

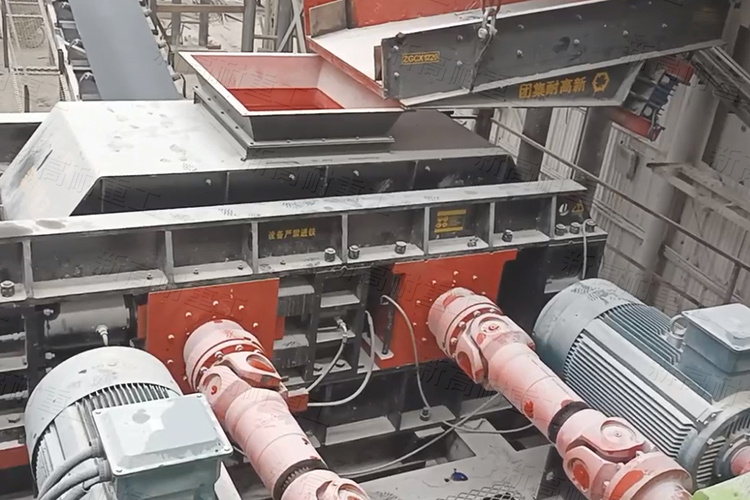

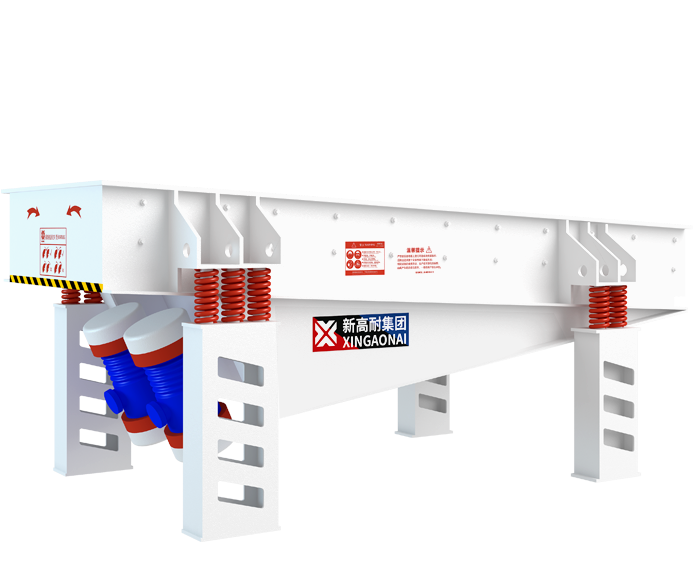

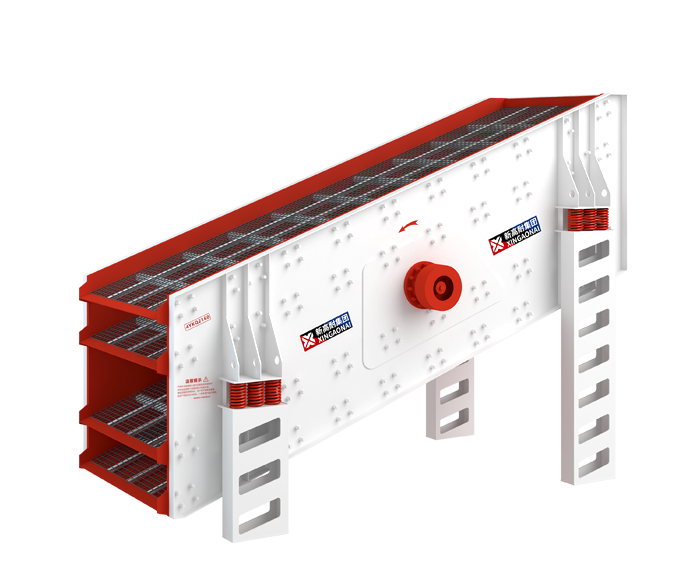

This upgrading of the production line is the fourth strong cooperation between the company and Xingaonai Heavy Industry after the previous three successful cooperations. This is not only a recognition of the results of previous cooperation, but also a further deepening of strategic cooperation based on a common vision. The professional team of Xin Gaonai Heavy Industry conducted an in-depth analysis of the bottlenecks of the old production line and proposed targeted solutions to ensure that the transformed production line would reduce energy consumption and emissions while increasing production capacity, responding to the international trend of green manufacturing. In this cooperation, Xingaonai Heavy Industry has injected new vitality into the project with cutting-edge high-performance technical equipment. It is not only a simple replacement of equipment, but also an in-depth optimization of the process flow. First of all, the vertical shaft impact crusher, with its high efficiency and energy saving characteristics, significantly improves the efficiency and particle size uniformity of raw material crushing, laying a solid foundation for the subsequent process; secondly, the introduction of the roller sand making machine ensures the fineness of the product. At the same time, it minimizes the powder output and improves the purity and use value of the raw materials; finally, the equipped vibrating screen ensures the accuracy and quality control of the final product with its excellent screening performance, meeting the requirements of high-end ceramics The production plant has strict requirements for raw materials.

Related configuration