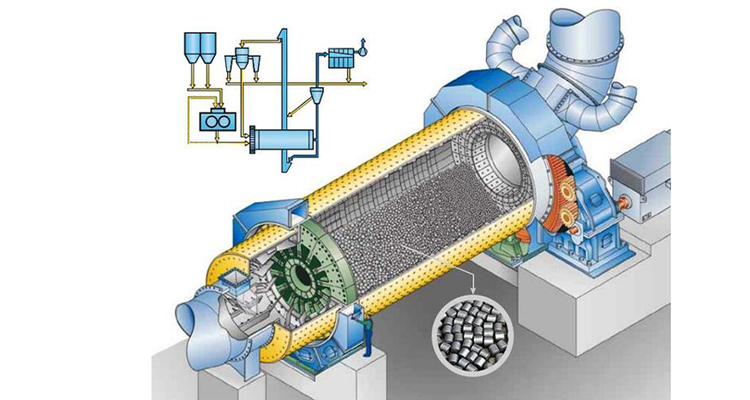

1、High yield and energy saving

The rod mill has a large processing ability, which can complete a large amount of sand making operations in a short period of time to meet the demand for high -production capacity. It is more energy -saving than traditional equipment, saving more than 40% of power, and effectively reduced production costs.

2、Wide range of applications

The rod mill has good effects on the crushing effect of various hard rocks, and can accept the larger feed particle size, reduce the pressure in the early breaks, and meet the needs of large -scale production.

3、Granularity adjustment

Suitable for various fineness modulus of medium, coarse, fine, and ultrafine sand,built-in fineness control device, the discharge can be equipped with a screening device to ensure that neither over-grinding nor unqualified products are mixed into the finished product.

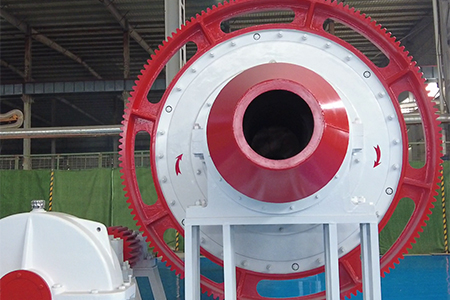

4、Uniform particle shape

According to the different needs of users, the grinding body can be replaced to meet the needs of ore grinding with different hardness, and the output particle size is uniform and the output is higher.