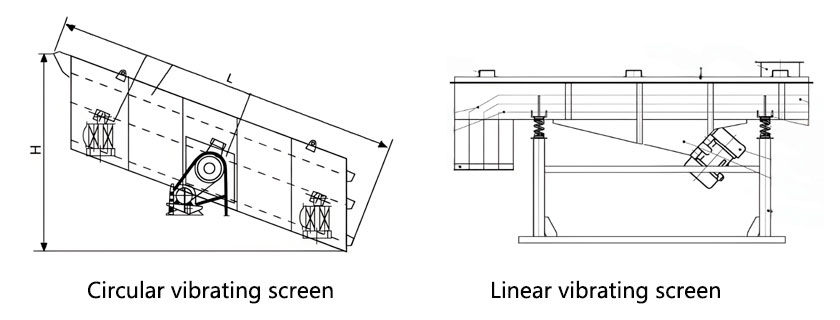

Differences Between Circular and Linear Vibrating Screen

Vibrating screen is an important screening machine used by various industries to classify materials according to particle size. It is a tool that downstream production feed particle size in industries such as aggregates, mining and construction depends on. Vibrating screens can be divided into circular vibrating screens and linear vibrating screens according to design and vibration form.

Different working principles

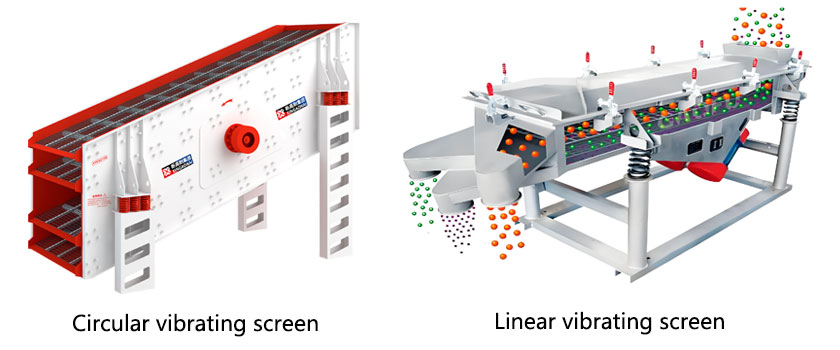

Circular vibrating screen: The vertical vibrating motor generates three-dimensional vibration, which makes the material move in a spiral motion on the screen surface, thereby achieving screening. The material enters from the center and gradually spreads outward. Fine particles pass through the screen and coarse particles are discharged from the discharge port. It is widely used in material screening in industries such as ore, coal, fertilizer, and building materials, especially for screening operations of medium-sized materials.

Linear vibrating screen: It is an efficient screening equipment, mainly used for grading, filtering or impurity removal of materials such as particles and powders. It generates linear vibration through the relative movement of two or more vibrating motors, so that the material moves along a straight line trajectory, thereby achieving the purpose of screening. It is suitable for fine screening and materials with relatively uniform particle size.

Different motion trajectories

Circular vibrating screen: The screen generates a circular or nearly circular vibration trajectory through an eccentric block or a vibrating motor. The material moves in a spiral shape and is suitable for screening medium-particle materials.

Linear vibrating screen: The vibration source is usually generated by two vibrating motors in opposite directions. The material moves in a straight line and is suitable for fine screening and grading.

Different processing capabilities

Circular vibrating screen: Unique design, the exciter is arranged above the center of gravity of the screen box, so that the elliptical long axis at both ends of the screen box presents a downward figure eight shape. This design can quickly disperse the material and slow down the material speed during discharge. Its arc-shaped screen surface increases the utilization area of the screen machine and effectively improves the processing capacity.

Linear vibrating screen: The processing capacity is relatively low, but the accuracy is higher. It is mainly used for screening fine particles, light specific gravity, and low hardness materials.

Different uses

Circular vibrating screen: Mainly used for screening coarse-grade materials with high specific gravity and high hardness. It is widely used in ore, sand and gravel, coal, building materials, fertilizer and other industries, especially for coarse screening and medium screening.

Linear vibrating screen: mainly used for materials with smaller particles and more uniform particle size. It is widely used in chemical, environmental protection, pharmaceutical, food and other industries, especially for fine screening and grading.

Different appearance and structure

Circular vibrating screen: The exciter is set above the center of gravity of the screen box, which is more conducive to the rapid dispersion of materials.

Linear vibrating screen: The exciter is set below the machine, and the body can adopt a fully enclosed structure, without dust spillage throughout the process, which is more conducive to environmental protection;

Different materials

Circular vibrating screen: usually thicker plates are selected, especially the box part, which is often made of manganese steel to cope with the strong impact of materials during screening.

Linear vibrating screen: mainly light plates or stainless steel plates.

Energy saving and environmental protection

Circular vibrating screen: The vibration is more uniform, the vibration frequency and amplitude are larger, and higher noise may be generated.

Linear vibrating screen: The vibration mode is relatively stable, and the energy consumption and noise are lower than the circular vibrating screen, which is suitable for working environments with strict noise control.

Different blocking phenomena

Circular vibrating screen: The material is thrown up to make circular motion, so the material is relatively dispersed and has strong bouncing force. Even if it is stuck in the screen hole, it can jump out, greatly reducing the blocking rate of the screen hole.

Linear vibrating screen: The material moves linearly on the screen surface. If the material has a large wet viscosity or uneven feeding, it is easy for the material to block the screen hole;

Different installation inclination angles

Circular vibrating screen: The installation inclination angle is large, usually around 15-20°, which changes the movement speed of the material and improves the screening efficiency to a certain extent.

Linear vibrating screen: The installation inclination angle is small, and the small inclination is convenient for process layout;

In general, the circular vibrating screen is an efficient screening equipment, suitable for screening of large flow and medium-sized particle materials, and the operation and maintenance are relatively simple. The linear vibrating screen is mainly suitable for fine screening and small and medium-sized materials, and can provide high-efficiency and uniform screening effects. The specific selection of which vibrating screen should be determined based on factors such as material characteristics (such as particle size, humidity, viscosity, etc.), screening requirements (coarse screening or fine screening), and processing capacity.

Article Title: Differences Between Circular and Linear Vibrating Screen

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/differences-between-circular-and-linear-vibrating-screen.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222