Xingaonai

Xingaonai

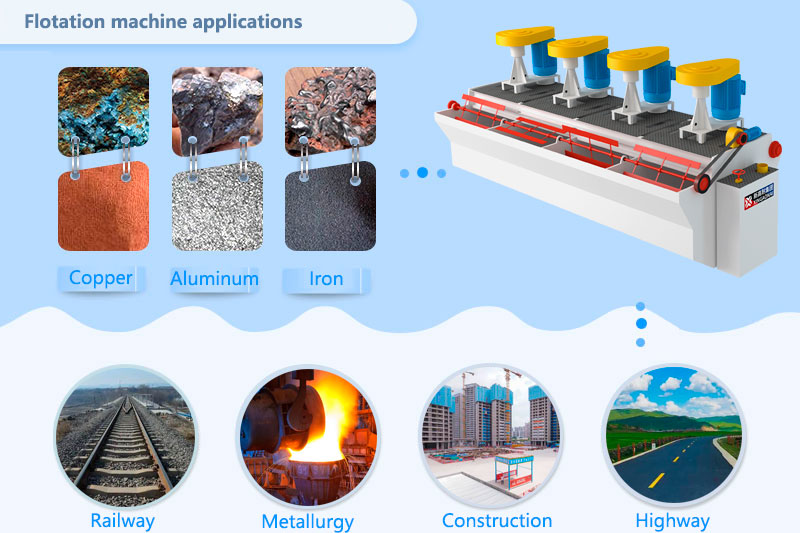

The flotation machine is a commonly used ore dressing equipment used to separate practical minerals from non-practical minerals in the ore. It separates practical minerals from non-practical minerals by utilizing the difference in affinity between minerals and bubbles in the ore. It is widely used in mining and processing industries to purify fine specific pollutants in industrial wastewater.

The flotation machine is mainly used to select metal minerals such as gold, silver, copper, iron, lead, zinc, molybdenum, nickel, and aluminum. It can also be used for the selection of ferrous metals and non-metals. It has the advantages of simple structure, convenient operation, and good mineral processing effect, and is widely used in mining and metallurgical industries.

The flotation machine is mainly composed of a flotation chamber, a mixing device, an aeration device, a mineralized foam discharge device, a motor, etc.

First, the ore is processed by crushing, grinding and other processes to form a slurry, which is fed into the tank of the flotation machine through the feed pipe. The ore and reagent in the slurry are then fully mixed with a stirring device to achieve the best flotation conditions. Then the bubble generator injects air or other gases into the bottom of the tank to generate a large number of fine bubbles. These bubbles will adhere to the surface of the practical mineral, making it buoyant. The practical minerals float to the liquid surface after combining with the bubbles to form bubbles. The non-practical minerals sink to the bottom to form waste slag. By controlling the injection amount of bubbles and the intensity of stirring, effective separation of practical minerals and non-practical minerals can be achieved. Finally, the waste slag discharge device discharges the waste slag from the bottom of the tank for subsequent treatment or disposal. The practical minerals in the bubbles are collected, usually through a concentration tank or other collection devices.

Various functions: Each tank has the triple functions of suction, slurry suction and flotation, forming a flotation circuit without any auxiliary equipment

High flotation efficiency: It has a gate device to adjust the pulp surface. It can control the liquid level by adjusting the gate height, so that useful foam is scraped out by the scraper, improving the flotation efficiency. The forward-inclined tank has small dead angles, fast foam movement speed and high processing efficiency

Reasonable circulation: The backward-inclined impeller has double-sided blades, the upper blades produce the upper circulation of the pulp, and the lower blades produce the lower circulation of the pulp. The pulp circulation is reasonable

Good suspension effect: The upper and lower double circulation of the pulp in the tank can minimize the precipitation of coarse particles, which is conducive to the suspension of coarse minerals

Large suction, wear-resistant and low consumption: The gap between the impeller cover plates is large, which effectively reduces the impact on the suction volume. When the impeller rotates, the internal pulp circulation increases its centrifugal force, improves the vacuum degree in the upper impeller cavity, and increases the suction volume; the impeller has a low circumferential speed, which prolongs the service life of wearing parts

Simple structure Convenient operation: SF type flotation machine is mainly composed of tank body, main shaft component with impeller, motor, scraper, transmission device and other parts. It is equipped with automatic control device of pulp surface, mechanical stirring, convenient adjustment, horizontal configuration, which is convenient for process change

Summary: Flotation machine realizes the separation of practical minerals and non-practical minerals by utilizing the difference in affinity between minerals and bubbles. Its working principle is based on the difference in hydrophilicity and hydrophobicity between minerals and bubbles, and realizes the flotation separation of minerals through stirring and mild bubble injection. Flotation machine has important application value in mining and metallurgical industries, and provides an effective tool for ore dressing.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Working-principle-and-structure-of-flotation-machine.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap