What is Alumina? What is Alumina Made of?

What is alumina?

Alumina is a high-hardness white solid inorganic compound, also known as aluminum trioxide. It is a stable oxide of aluminum and oxygen and is also the main component of bauxite. In nature, alumina exists in the form of minerals such as corundum, with extremely high hardness and melting point.

What color is alumina

The color of alumina is white. Usually, it appears as a white amorphous powder, tasteless, odorless, high hardness, easy to absorb moisture without deliquescing.

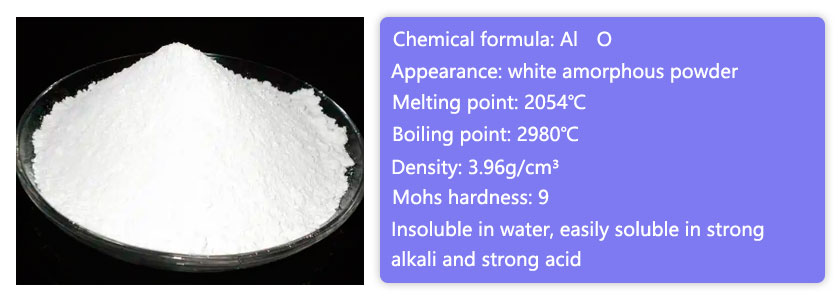

Physical properties of alumina

Alumina has excellent wear resistance and corrosion resistance, with a melting point of up to 2050℃, a boiling point of 2980℃, a density of 3.96g/cm³, and a Mohs hardness of 9, second only to diamond. In addition, alumina is a good insulating material, non-conductive, and has good thermal conductivity.

Chemical properties of alumina

Alumina has stable chemical properties and is a typical dioxide with strong acid and alkali resistance. It is insoluble in water and organic solvents at room temperature. It can react with some metal ions and non-metallic elements, such as alum formed with aluminum, loess formed with iron ions, and aluminum oxide formed with oxygen.

What is aluminum oxide made of?

Bauxite is the main raw material for making aluminum oxide. It is an aluminum oxide ore with a content of 40%-70%. The production process of aluminum oxide is delicate and complex, mainly including several important links such as raw material crushing, slurry making, dissolution, sedimentation, refining and separation, roasting and mother liquor circulation.

Crushing equipment

The jaw crusher is recommended for crushing equipment. The jaw crusher has the characteristics of large crushing ratio, high output, uniform product particle size, simple structure, reliable operation, convenient maintenance, and economical operating costs. It is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries.

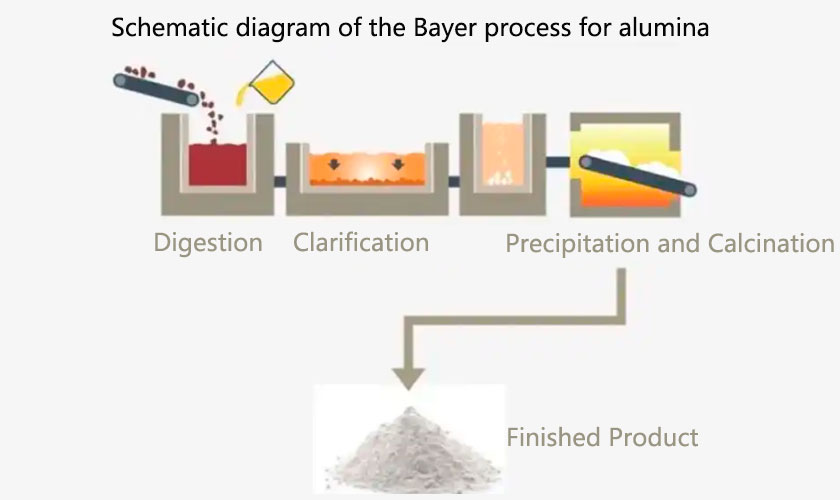

The process flow of the Bayer process:

First, the crushed bauxite is mixed with caustic soda to prepare a raw ore slurry that meets the standards. The raw ore slurry is desiliconized, and at the same time, it is diluted and separated by red mud sedimentation to obtain a pure ore slurry. The ore pulp is separated into aluminum hydroxide by the method of seed decomposition. Finally, after separation, washing and roasting, aluminum hydroxide is converted into high-purity alumina.

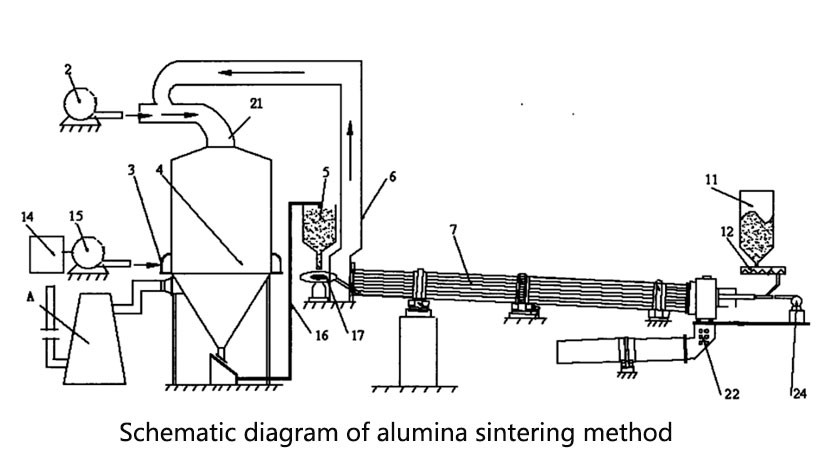

Sintering process:

First, bauxite, limestone and caustic soda are finely ground in proportion to form a slurry. Then, after sintering, dissolution, desiliconization and other processes, the sodium aluminate solution is taken out. The sodium aluminate solution is then decomposed by carbonation to analyze and effectively separate aluminum hydroxide and sodium carbonate mother liquor. Finally, by roasting aluminum hydroxide, a high-purity alumina product is obtained.

Uses of alumina

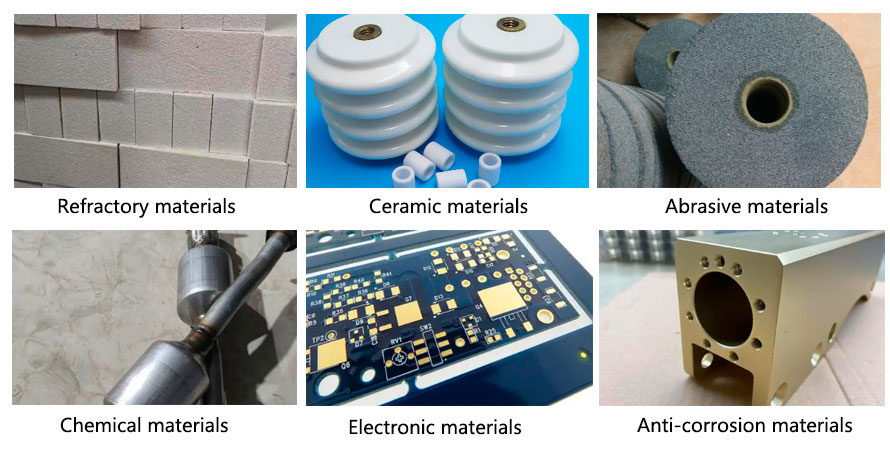

Refractory materials: Alumina has the characteristics of high temperature resistance, corrosion resistance and mechanical properties, and is a commonly used refractory material. It is widely used in the manufacture of steelmaking furnaces, high-temperature furnaces, refractory bricks, etc.

Ceramic materials: Because alumina has the characteristics of high strength, insulation and high temperature resistance, it is widely used in the manufacture of ceramic materials, such as ceramic knives, ceramic tiles, ceramic utensils, etc.

Grinding materials: Alumina has the advantages of high hardness and good wear resistance. It is a good grinding material and is often used in the manufacture of grinding wheels, sandpaper, etc.

Chemical materials: Alumina is a good carrier for preparing catalysts. It can load active substances onto the surface, giving it good thermal properties and stability. It is often used in chemical catalysts and automobile exhaust purification catalysts.

Electronic materials: Because alumina has good thermal conductivity and insulation, it is the main raw material for manufacturing electronic components, such as capacitors and integrated circuit packaging.

Filler: Alumina as a filler can enhance the hardness, strength and wear resistance of the material, and is often used in the manufacture of rubber, artificial marble, etc.

Anti-corrosion materials: Alumina has anti-corrosion properties and can be applied on the metal surface to form a protective film to prevent corrosion of the metal.

Article Title: What is Alumina? What is Alumina Made of?

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/What-is-Alumina-What-is-Alumina-Made-of.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222