Xingaonai

Xingaonai

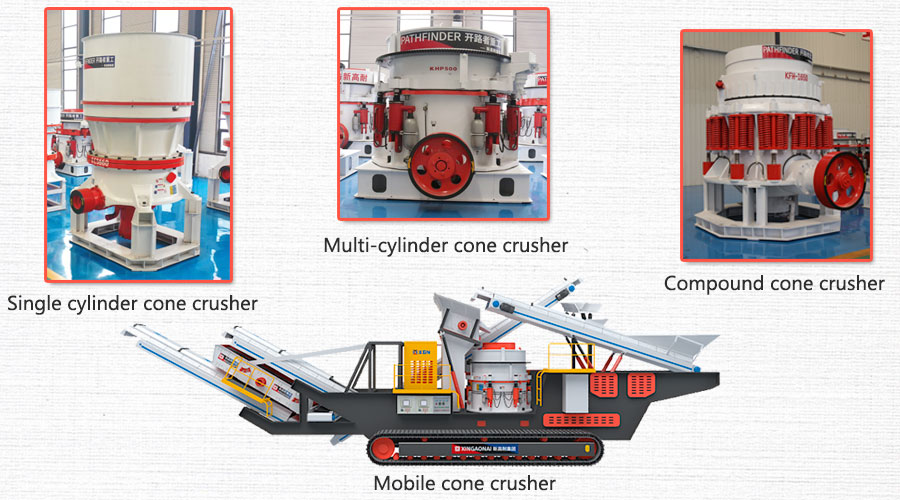

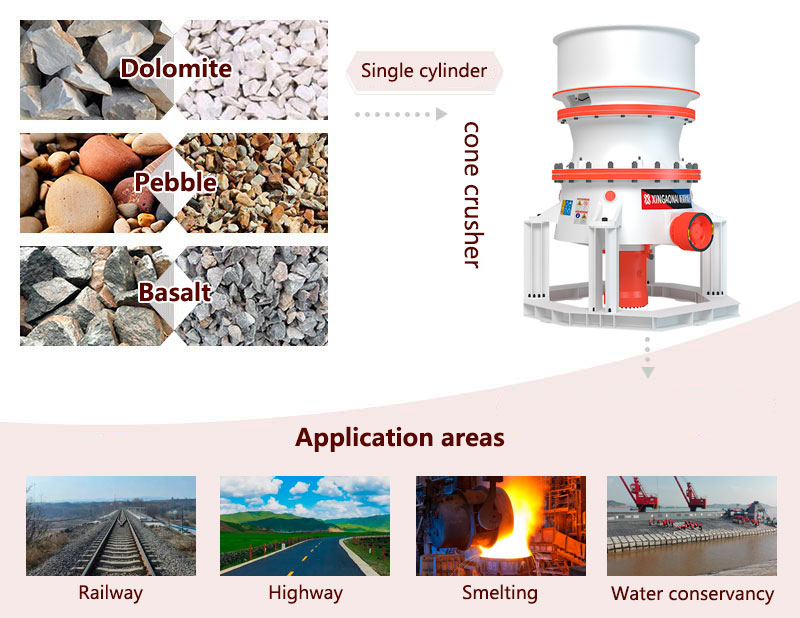

Cone crusher is an important equipment for raw materials in metallurgy, construction, road construction, chemical and silicate industries. It is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries with its efficient crushing performance. It can crush stones into a particle size of 0-50mm and is suitable for various complex working environments. There are many types of cone crushers, including single-cylinder, multi-cylinder, full hydraulic and compound series, in addition to flexible mobile cone crushers. The prices of equipment with different models, configurations and functions vary. Below, New High-resistant Heavy Industry will give you a detailed introduction to the types of cone crushers.

The single-cylinder cone crusher, developed with advanced crushing technology, uses only one hydraulic cylinder and integrates mechanical, hydraulic, electrical and intelligent control technologies. It is a new crushing design structure, optimized laminated crushing cavity type and fully intelligent automatic control system. It has performance characteristics that traditional cone crushers do not have. It has a constant cavity design, a longer service life of the liner, no need to fill the mortar wall, and replacement and maintenance are very quick and convenient. It can be widely used in medium crushing, fine crushing and ultra-fine crushing operations.

Working principle of single-cylinder cone crusher:

When the single-cylinder cone crusher is working, the motor drives the small gear of the crusher, the small gear drives the large gear, and the large gear assembly drives the eccentric sleeve assembly and the main shaft assembly to revolve in the copper bushing with the theoretical vertical line as the center. The main shaft assembly can realize self-rotation in the eccentric copper sleeve with the center line of the main shaft. When the material is added to the crushing chamber, the main shaft assembly slowly rotates in the eccentric copper sleeve under the resistance of the material. The running trajectory of the inner cone seems to swing back and forth in the crushing chamber while rotating slowly. The material is squeezed and crushed by the swinging inner cone, and the crushed material is discharged from the discharge port.

The multi-cylinder hydraulic cone crusher has multiple hydraulic cylinders, supplemented by multiple one-to-one nitrogen cylinders, which is suitable for crushing various ores and rocks of medium and above hardness. The machine adopts PLC+touch screen automatic control system to ensure the safe operation of the equipment. In addition, the discharge port is adjusted by a hydraulic motor, and the lubrication system adopts a small-volume hydraulic lubrication combined oil station and a fixed shaft structure design, which is easy to use and greatly reduces the basic investment of the equipment. Finally, all parts of the equipment can be disassembled from the top and side, and the equipment is easy to maintain. It is a new generation of products that replace spring cone crushers and newer generation hydraulic cone crushers in the mining and construction industry.

Working principle of multi-cylinder hydraulic cone crusher:

The multi-cylinder hydraulic cone crusher adopts an extrusion working principle. The motor drives the eccentric sleeve to rotate through a V-belt, a transmission shaft, and a bevel gear pair, and the moving cone performs a swivel motion driven by the eccentric sleeve. After the material enters the crushing chamber from the material port, it is squeezed, ground, and rubbed by the mutual impact of the eccentric shaft and the mortar wall, thereby producing a crushing effect. The crushed material is discharged from the machine cavity from the lower discharge port. The hydraulic insurance system can remove the faulty objects from the support sleeve and the fixed cone through hydraulic pressure when the machine has an iron fault or a stuck phenomenon, which greatly reduces the maintenance rate while playing a good insurance role.

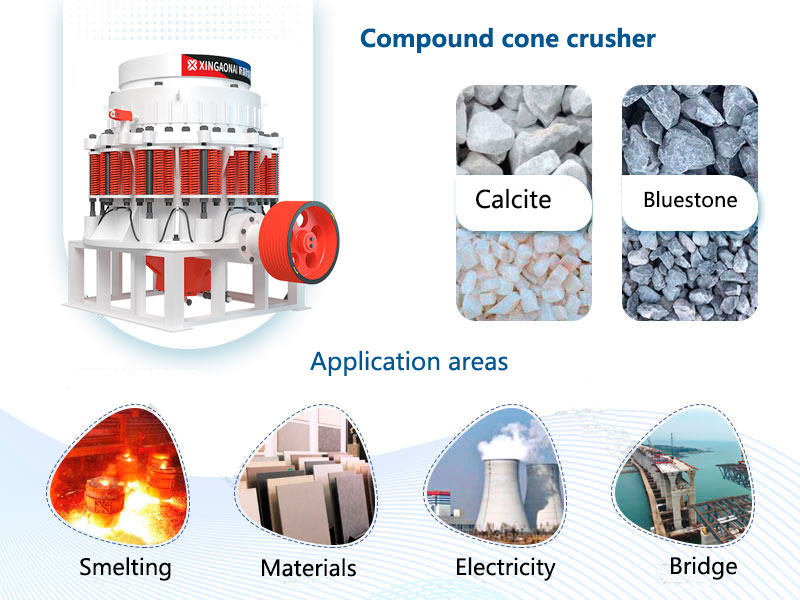

The compound cone crusher is a new type of cone crushing equipment that is upgraded and improved on the basis of the inclined rotary cone crusher. It mainly optimizes the structure of the cone neck and cup-shaped wall, improves the crushing efficiency and production capacity, and also adds hydraulic adjustment outlets and protection devices for easy operation and maintenance. It is suitable for medium and fine crushing of medium-hardness materials such as stone, ore, and construction waste.

Working principle of compound spring cone crusher:

When the compound high-yield cone crusher is working, the motor drives the eccentric sleeve to rotate through the V-belt, large pulley, transmission shaft, small bevel gear, and large bevel gear. The main shaft rotates and swings under the force of the eccentric sleeve, so that the crushing wall is sometimes close to and sometimes away from the mortar wall, so that the material is constantly impacted, squeezed and bent in the annular crushing chamber composed of the fixed cone and the moving cone. After multiple extrusions, impacts and bending, the material is crushed to the required particle size and discharged from the bottom.

As the name suggests, the mobile cone crusher is a movable cone crusher. It combines the advantages of cone crusher and mobile crushing station, and can be flexibly transferred to different sites to meet various crushing needs. This equipment is mainly used to process ores and rocks of various hardness, and crush them into the required particle size by extrusion, bending and shearing.

Working principle of mobile cone crusher:

Mobile cone crusher mainly relies on its internal cone crushing mechanism. When the material enters the crushing chamber, it is squeezed and sheared between the moving cone and the fixed cone to achieve crushing. The moving cone is driven by the eccentric sleeve to make a swiveling motion, so that the material is continuously impacted and ground in the crushing chamber, and finally achieves the desired crushing effect.

Whether you need an efficient single-cylinder cone crusher, a multi-cylinder hydraulic cone crusher for high-hardness ores, or a flexible mobile cone crusher, choosing the right model and configuration is crucial to improving production efficiency. Understanding the characteristics and prices of different models will help you make more informed purchasing decisions.

If you want to know more about the crusher, please call or consult online, leave a message, and Xin Gaonai Heavy Industry will send professionals to answer your questions.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/What-are-the-commonly-used-cone-crushers.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap