Xingaonai

Xingaonai

Hematite is a common iron ore. Due to its high iron content, its color is usually reddish brown. It is formed by chemical reactions between iron oxide ore and iron ore. The main component of iron oxide ore is iron oxide, which reacts chemically with iron ore with high iron content in the air to form hematite.

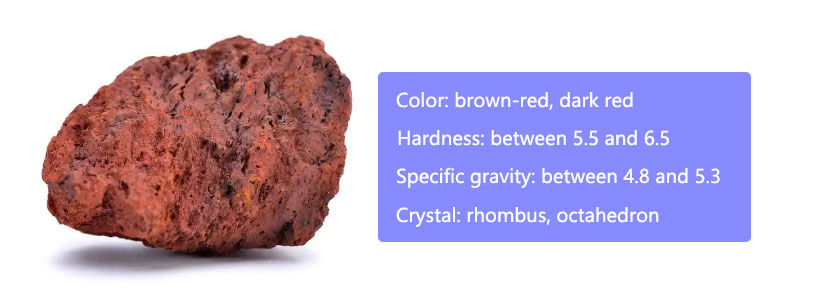

Hematite is generally brown-red or dark red, with a hardness between 5.5 and 6.5, a specific gravity between 4.8 and 5.3, rhombus or octahedral crystals, and often forms granular, blocky and vein-like ore bodies. It is an opaque mineral with strong magnetism and good magnetic conductivity. However, when heated to a high temperature of more than 400°C, the magnetism disappears. Although hematite contains iron, it does not have the characteristics of a metal as a mineral, so hematite does not belong to the category of metal substances.

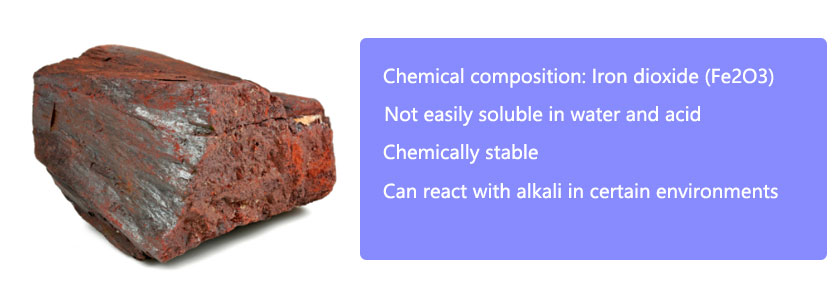

The chemical composition of hematite is iron dioxide (Fe2O3), which generally contains a small amount of titanium, manganese, chromium and other elements. It is not easy to dissolve in water and acid. Its chemical properties are quite stable, but it will react with alkali to a certain extent. In addition, hematite is easy to be reduced and is often used as an important raw material in iron smelting, metallurgy and other industries.

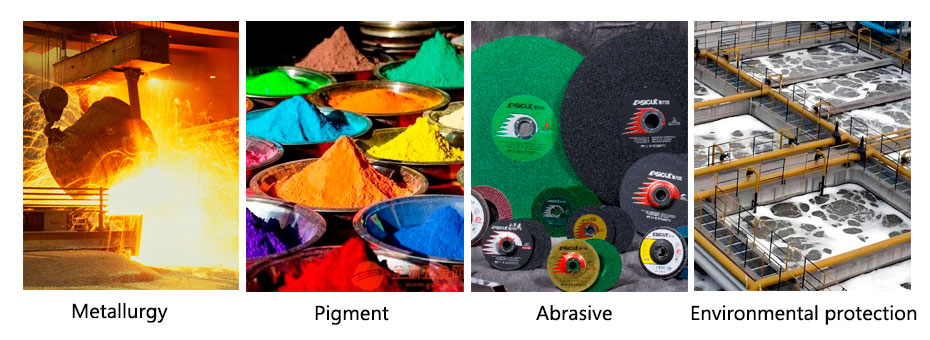

Metallurgical industry: As a raw material for steel smelting, hematite can be refined into iron concentrate after crushing, magnetic separation, flotation and other mineral separation processes, and then used in the production of steel.

Pigment industry: Due to its bright and stable color, hematite is also used as a pigment, especially in paints, ceramics and building materials.

Abrasive industry: Due to its moderate hardness, hematite is also used as an abrasive for grinding and polishing metals, glass and other materials.

Environmental protection: The adsorption properties of hematite are used to treat heavy metal ions and organic pollutants in wastewater, thereby achieving the purpose of purifying water quality. In addition, hematite can also be used as a soil conditioner to improve soil fertility and water retention, playing an important role in the field of environmental protection.

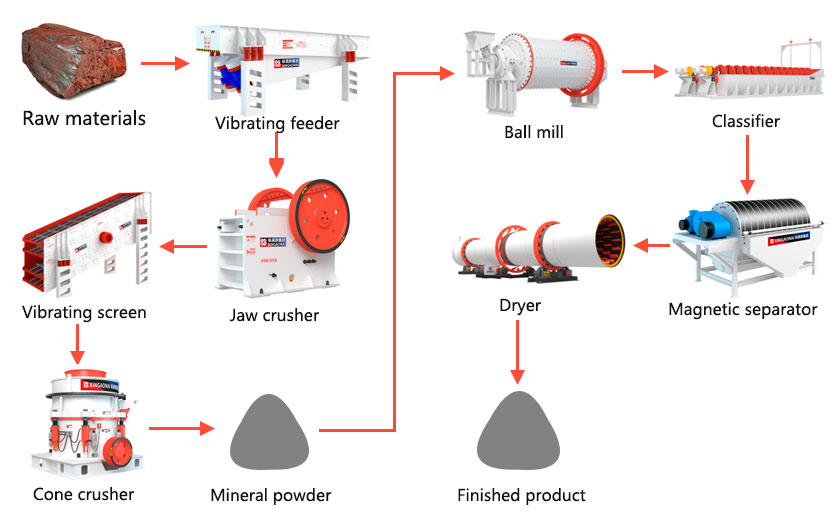

Required equipment: vibrating feeder, jaw crusher, vibrating screen, Cone Crusher, ball mill, classifier, magnetic separator, dryer, belt conveyor, etc.

The ore material is mined, and the jaw crusher performs primary crushing. After the cone crusher crushes it to a reasonable fineness, the feeder evenly feeds it into the ball mill to grind the ore. The ground sand and gravel fine material is fed into the spiral classifier. With the help of the different specific gravity of the solid particles and the different sedimentation speeds in the slurry, the ore is washed and graded. The magnetic minerals and non-magnetic minerals in the mixture are separated by the magnetic separator to form iron concentrate. After dehydration and drying by the filter and dryer, the dry iron concentrate can be obtained.

In general, hematite is an important mineral resource with the characteristics of high hardness, wear resistance, corrosion resistance, stability, etc. It is widely used in metallurgy, plastics, abrasives, environmental protection and other fields. With the development and progress of society, the processing technology of hematite is constantly improving, and I believe that the application field of hematite will be broader in the future.

Article Title: Uses and production process of hematite

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Uses-and-production-process-of-hematite.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap