Xingaonai

Xingaonai

Gyratory crusher is a cone crusher, also known as compound crusher. It is widely used in the coarse crushing of ores and rocks of various hardness, such as mining, construction, cement, metallurgy, chemical industry and other industries. It is suitable for large and medium-sized ore dressing plants and large quarries for coarse crushing of hard and medium-hard ores. Below, New Gaonai Heavy Industry will take you to learn more about gyratory crusher.

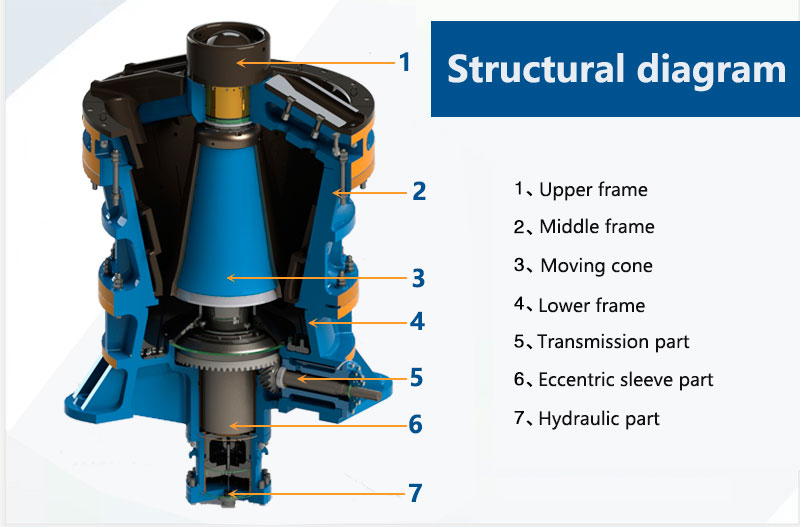

Gyratory crusher is mainly composed of beam part, upper, middle and lower frame part, moving cone part, eccentric sleeve part, transmission part and hydraulic cylinder part.

The working principle of gyratory crusher is to use the motor to drive the crushing cone through the pulley and bevel gear to drive the gyratory motion of the crushing cone in the cone cavity of the shell, produce extrusion, splitting and bending effects on the material, and coarsely crush ores or rocks of various hardness. The size of the discharge port can be changed by adjusting the hydraulic cylinder at the bottom of the moving cone, which is convenient for adjusting the product particle size; at the same time, the hydraulic cylinder also provides iron protection function. When an object that cannot be crushed enters the crushing chamber, the hydraulic cylinder can automatically make the moving cone fall to release the object and protect the crushing chamber.

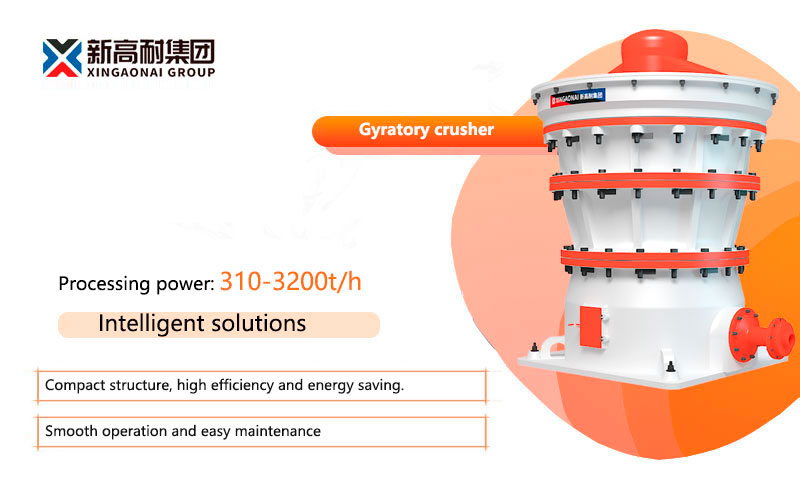

Gyratory crusher has the advantages of compact structure, high efficiency and energy saving, stable operation, and easy maintenance. It is widely used in the mining industry. Compared with other crushing equipment, gyratory crusher has the following characteristics:

It has better crushing effect on materials with higher hardness;

It is not suitable for materials with higher humidity;

It has poor crushing effect on sticky materials;

It has better crushing effect on fine materials.

Gyratory crusher is a commonly used crushing equipment with the advantages of high efficiency, high discharge port, low power consumption and reliable operation. This article introduces its structure and working principle, which can help us use and maintain the crusher correctly, improve its service life and crushing efficiency, and at the same time, the maintenance and maintenance of the equipment cannot be ignored.

Author:[Xingaonai]

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: [email protected]

Whatsapp: 8617761642222

Article Title: The structure and working principle of gyratory crusher

Reprint URL: https://www.xgncrusher.com/Industralnews/The-structure-and-working-principle-of-gyratory-crusher.html

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap