Xingaonai

Xingaonai

Cone crusher and impact crusher are two common crushing equipment. Both are secondary crushing equipment in sand and gravel production lines. They differ in working principle, applicable materials, discharge particle size, production capacity, input cost and pollution degree. The following are their main differences:

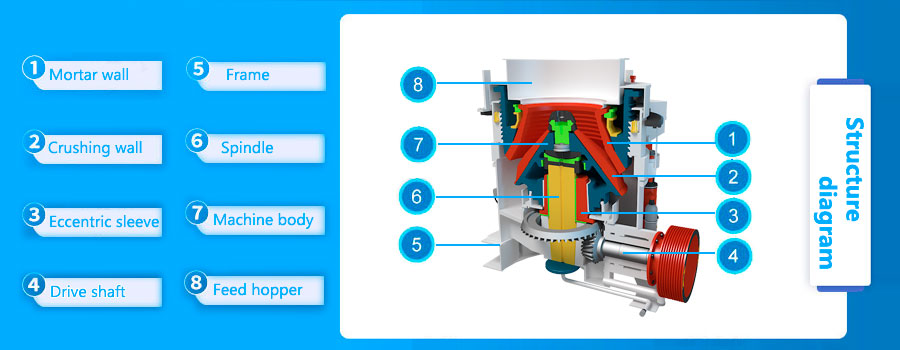

Cone crusher: When the material enters the cone crushing chamber, it is subjected to certain extrusion, stretching and shearing forces, so that the material is crushed multiple times in the crushing chamber. The finished product particles are finer, with less needle-like content and good particle shape. The produced materials are generally fine powder or medium-fine crushed materials.

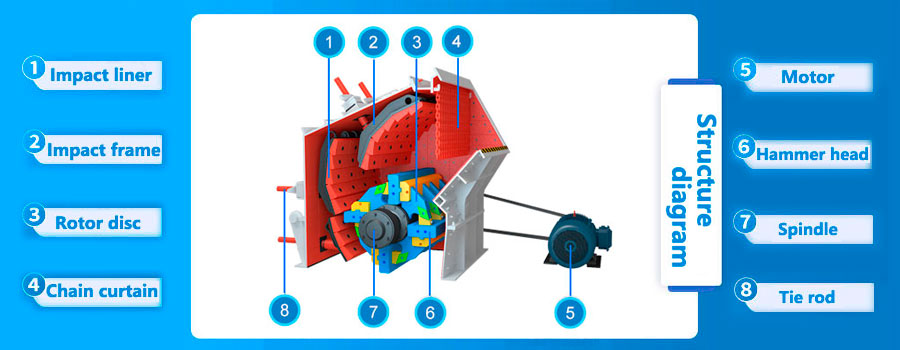

Impact crusher: When the material enters the crushing chamber of the impact crusher, it is subjected to the friction between the impact plate and the cone and the weight of the material itself, and moves downward and is squeezed and impacted by the material itself. When the material contacts the impact plate, it will be rebounded and hit the cone, thereby achieving the crushing effect.

Cone crusher: The structure is relatively simple. They are mainly composed of a body, a frame, a main shaft, a mortar wall, a crushing wall, a cone sleeve, a cone pin, an adjustment sleeve, a cone sleeve liner and a liner screw.

Impact crusher: The structure is relatively complex. Its body has two bearing seats, one of which is composed of several bearings, and the other is connected to the body by a bearing seat. The main shaft of the crusher is directly mounted on the frame.

Impact crushers and cone crushers are commonly used to crush materials with different hardness ranges. However, for some unreasonable stone hardness, considering economy and practicality, the two can also be used interchangeably.

Cone crusher: It mainly crushes some materials with higher hardness, such as granite, calcite, basalt, tuff, iron ore, river pebbles, etc., which are suitable for crushing hard materials.

Impact crusher: It mainly crushes materials with lower hardness, such as limestone, limestone, quartz stone, coal gangue, construction waste, etc. Suitable for crushing medium hardness and below tough, brittle materials.

Cone crusher: It has high production capacity, combines high crushing cavity type with high crushing frequency, and adopts PLC+touch screen full-automatic control system, which effectively improves its material processing capacity and is suitable for large-scale high-yield production line operations. In general, the production capacity of cone crusher is between 55-2181t/h.

Impact crusher: It has relatively low production capacity, but good crushing effect. It adopts a sturdy heavy rotor structure, which improves the material processing capacity and crushing ratio, thereby improving its crushing capacity. It is suitable for small and medium-sized stone plants with strict requirements on particle shape. In general, the production capacity of impact crusher is between 90-1550t/h.

Cone crusher: The price of cone crusher is more expensive than that of impact crusher, and the initial investment is relatively large, but the service life of wearing parts is long, it is more worry-free to use, and the later maintenance cost is low.

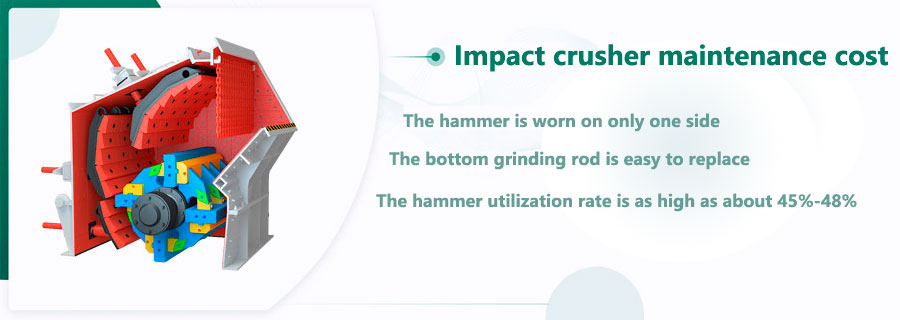

Impact crusher: It is relatively cheap and low-cost when purchased in the early stage, and it can be bought for tens of thousands of yuan, but the wearing parts are easy to damage, such as the impact plate and hammer head, which need to be replaced after multiple uses, and the later maintenance cost is high.

6. Different discharge particle types

Cone crusher: It can be divided into coarse, medium, fine, and ultra-fine types. The crushed material is finer and more powdery, with the advantages of low energy consumption and low noise.

Impact crusher: When crushing materials, it also has a certain function of discharging particle shaping. The produced material particles are cubic, uniform in size, reasonable in gradation, and beautiful in particle shape.

7. Different pollution levels

The noise pollution and dust pollution of the impact crusher are large; the noise and dust pollution of the cone crusher are relatively small.

In summary, the impact crusher and the cone crusher each have their own advantages and disadvantages. Which equipment should be selected in actual production? The specific needs are selected according to different material hardness, input and output particle size, output value, etc. For small stone production lines, impact crushers can be used. For large stone production lines with hard materials, cone crushers are better. If the requirements for particle shape are very strict, the corresponding equipment can be added appropriately. If you want to know more about crushers, please call or consult online, leave a message, and Xin Gaonai Heavy Industry will send professionals to answer your questions.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/The-difference-between-impact-crusher-and-cone-crusher.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap