Xingaonai

Xingaonai

Spiral classifier is a commonly used grading equipment in the production process. It is widely used in mining, metallurgy, building materials and other industries. It is mainly used for material grading and separation to improve the quality of finished materials. As an efficient and reliable grading equipment, it has a simple structural design and working principle, and plays a major and important role in material grading applications. It has the advantages of simple structure, convenient operation and low energy consumption, and is favored by mining companies. New Gaonai Heavy Industry will give you a detailed introduction to the spiral classifier.

The spiral classifier drives the material to be graded in the machine through the rotation of the spiral blade. When the mixed material enters the classifier, the heavier material particles will settle to the bottom with the liquid, and the lighter material particles will be sucked into the slag discharge port, thereby completing the material screening process.

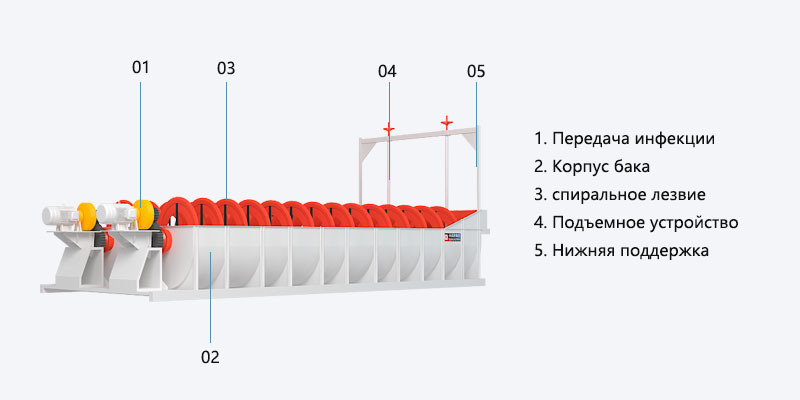

The spiral classifier is mainly composed of spiral blades, feed port, trough body, discharge port, slag discharge port, lifting device, transmission mechanism, etc. Among them, the spiral blade is the core component of the classifier, and its shape and length will directly affect the grading effect of the material. The material of the spiral blade is also one of the key factors affecting the service life of the spiral classifier.

Spiral classifiers are widely used in many industries:

In the mining field, it is mainly used for the washing and grading of ore materials, and can obtain ore products of different particle sizes. It can also be used for ore dehydration.

In the metallurgical industry, during the pretreatment of metal ores, the ore is graded to provide raw materials of suitable particle size for subsequent smelting.

In the environmental protection industry, in the fields of sewage treatment and sludge treatment, spiral classifiers can be used for solid-liquid separation to reduce the difficulty of subsequent treatment.

In the chemical industry, spiral classifiers are widely used in the grading and dehydration of various chemical raw materials. The spiral classifier has won the favor of the chemical industry for its efficient and reliable grading effect.

Good grading effect: under the action of centrifugal force and gravity during the grading process, the materials can be effectively separated and graded.

Large processing capacity: The spiral classifier has a simple structure and a small equipment size, but the processing capacity is very large, which can meet the needs of factories of various sizes.

Simple structure and easy maintenance: The spiral classifier has a simple structure, is easy to maintain and convenient to maintain, and reduces the maintenance cost of the factory.

Energy saving: The material conveying and grading are completed by spiral rotation, without excess energy consumption, which effectively saves energy.

In practical applications, it is necessary to select a suitable classifier according to the type of material and grading requirements, and pay attention to daily maintenance and maintenance to ensure that the machine can operate effectively for a long time. If you want to know more about the spiral classifier, you can contact us by phone: 8617761642222 or email: sales@xgnchina.com.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Spiral-classifier-structure-and-working-principle.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap