Xingaonai

Xingaonai

Pyrite is a common ore, generally formed in sedimentary rocks or rocks related to intrusive rocks. The formation process is related to geophysical and chemical processes. After many geological changes and chemical reactions, the pyrite minerals seen today are formed. Pyrite is similar to the precious metal gold and is also called fool's gold.

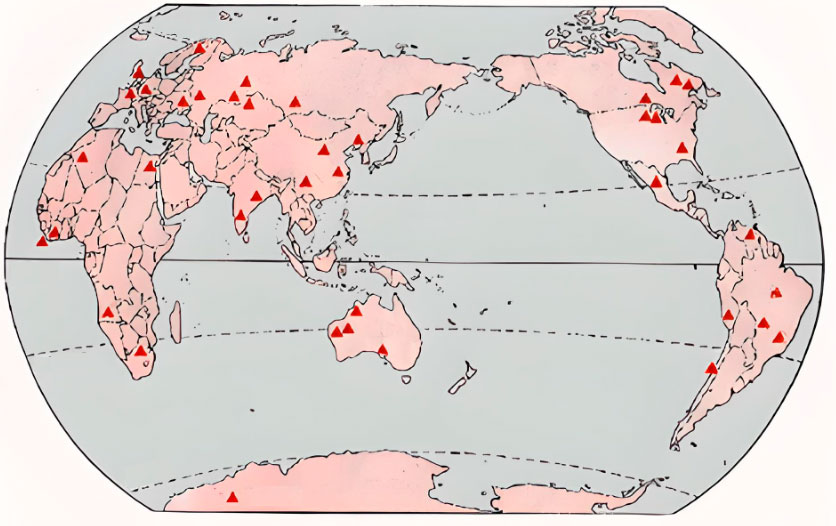

Pyrite is mainly found in: the United States and Canada in North America; Spain, Germany, Sweden and other countries in Europe; China, India, Russia and other countries in Asia.

Pyrite is an important sulfide mineral, with magnetite and hematite as the main components. It is mostly brown and light yellow, with a metallic luster. The hardness is 6-6.5 and the density is 4.9~5.2. It is generally cube-shaped, dodecahedral, and a few are octahedral, etc. The aggregates are granular, blocky, nodular and strawberry-shaped.

Under humid conditions, pyrite will oxidize into ferrous sulfate, and will undergo thermal decomposition at around 400°C, releasing elemental sulfur, which reacts with oxygen to become sulfur dioxide gas.

Pyrite has high hardness, low friction coefficient, and can be magnetized, so it is often used to make magnets. Pyrite can also be processed into various iron products, such as ferroalloys, iron powder, iron blocks, etc., and is widely used in construction, automobiles, machinery, ships and other industries.

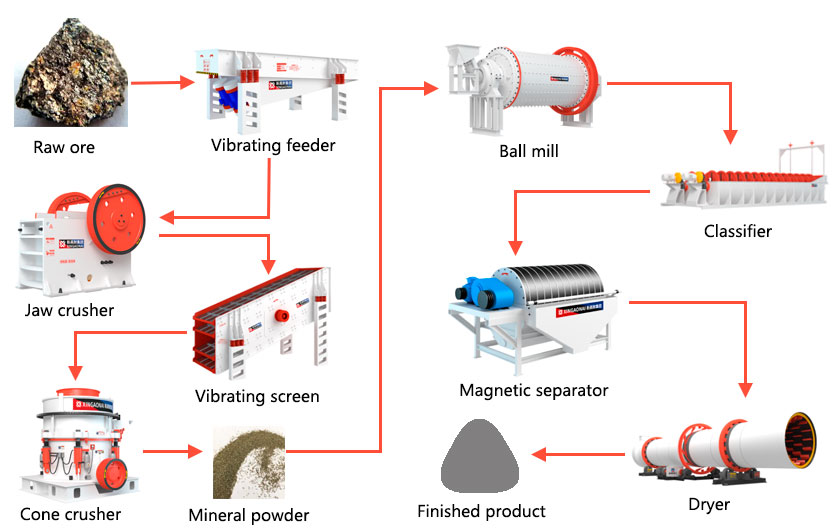

Ore dressing is mainly to separate pyrite from the original ore, remove its impurities, and improve the ore grade. This process involves multiple links and multiple equipment. The main process of ore dressing is crushing, screening, grinding, grading, sorting, and mineral dehydration.

First, crushing equipment

The first step in pyrite beneficiation is crushing, crushing the original ore to a suitable size. Common crushing equipment includes jaw crusher, Cone Crusher and impact crusher. Jaw crusher is mainly used as primary crushing equipment, and cone crusher is mainly used for medium and fine crushing.

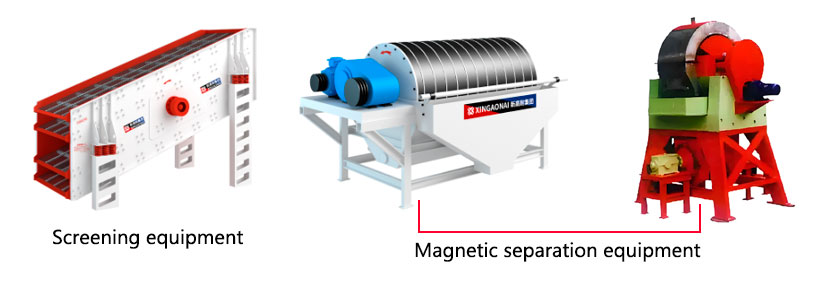

Secondly, screening equipment

The main function of screening equipment is to classify the crushed ore particle size according to size to meet the uniform particle size required for the beneficiation process. The main screening equipment is vibrating screen.

Again, magnetic separation equipment

We know that pyrite has a certain degree of magnetism. In the beneficiation process, common magnetic separation equipment is permanent magnetic drum magnetic separator and high gradient magnetic separator.

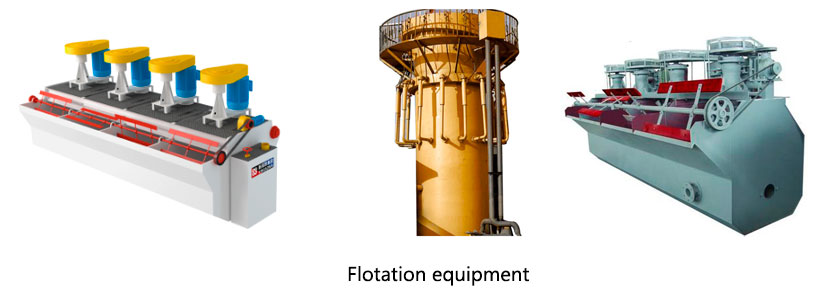

Finally, flotation equipment

In the beneficiation process, flotation equipment also plays a very important role, mainly used to separate valuable metals and impurities in pyrite. Common flotation equipment includes trough flotation machine and flotation column.

In addition to the above required equipment, some auxiliary equipment is also required for beneficiation, such as feeder, conveying equipment, dehydration equipment, etc.

In short, pyrite is a very important mineral resource, and the separation and purification of pyrite is completed through the beneficiation process. The crushing equipment, screening equipment, magnetic separation equipment, flotation equipment and auxiliary equipment required for pyrite beneficiation are briefly introduced to create greater value for the subsequent utilization of pyrite.

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap