Xingaonai

Xingaonai

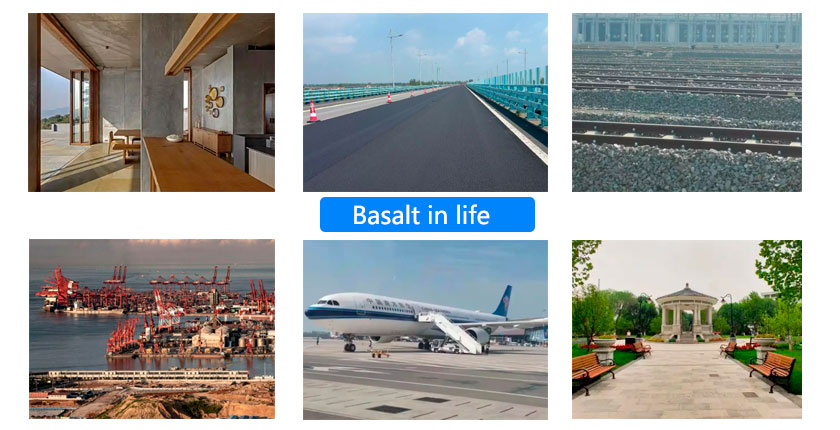

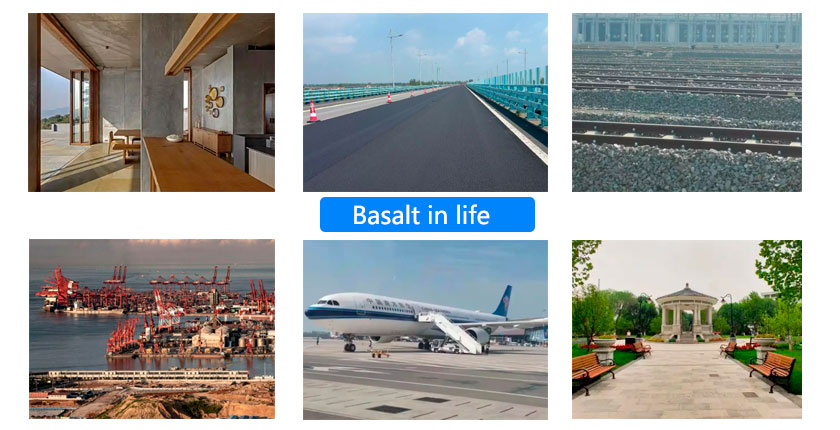

In daily life, basalt can be seen in many places. For example, the wall and floor decoration inside and outside the house where we live, and when we go out, we can see basalt on the road where cars are driving, on the railway like a giant steel snake, at the port when we go out to sea by ship, and in the vast airport. So do you know how basalt is formed? What is the hardness of basalt? What is the density of basalt? Is basalt harder than steel? What are the applications of basalt? Xingaonai Heavy Industry will take these questions to learn more about basalt.

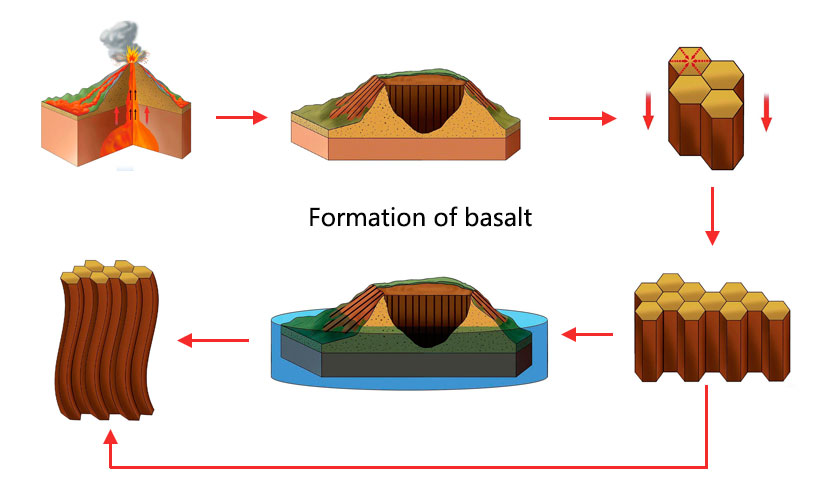

Basalt is an igneous rock related to volcanic activity. It is related to the contraction and cooling of the earth's interior. When the pressure and temperature inside the earth drop, it begins to crystallize and form different mineral rocks. Under high pressure and high temperature conditions, some minerals in basalt will change, resulting in different chemical composition and characteristics of basalt. These changes are the process of the formation of the earth's crust.

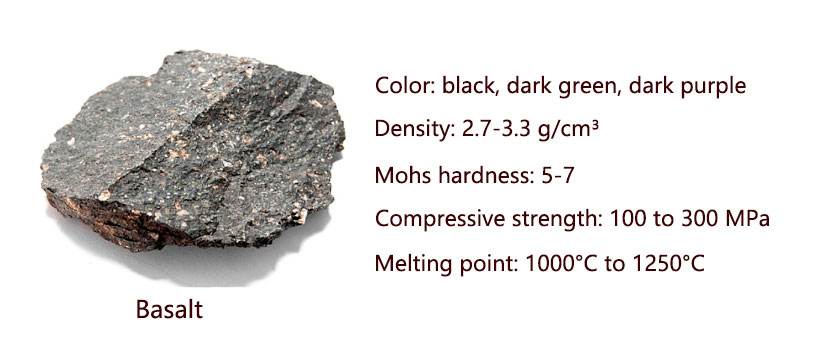

The Mohs hardness of basalt is about 5-7, and the Mohs hardness of steel is between 5-6, so basalt is a little harder than steel, and the hardness of the two is not much different.

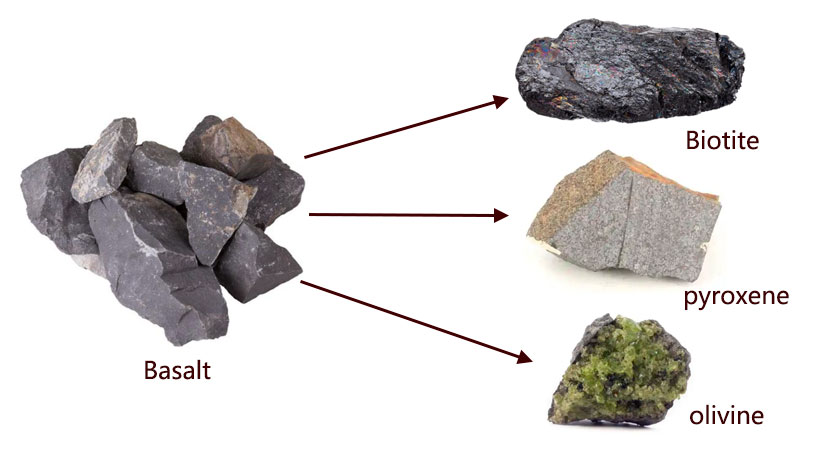

Basalt is widely distributed on the earth and is the most common rock. Because its basalt is composed of minerals such as biotite, pyroxene, and olivine, it is also called biotite pyroxene basalt. During the evolution and formation of basalt, serpentine, diorite, garnet, etc. may also appear.

Basalt generally appears black, dark green, dark purple, etc., and the color mainly depends on the mineral composition and formation environment.

The density of basalt is generally between 2.7-3.3 grams per cubic centimeter (g/cm³), and the Mohs hardness is usually between 5-7. Basalt has strong permeability and poor water absorption, with a compressive strength of about 100 to 300 MPa and a melting point of 1000°C to 1250°C.

Basalt is a typical alkaline extrusive rock, and its main chemical components are silicon dioxide, iron oxide, aluminum oxide, calcium oxide and magnesium oxide. Among them, the highest silicon dioxide content is about 45% to 52%, aluminum oxide and calcium oxide are 15% and 10% respectively, in addition, it also contains a small amount of sodium oxide and potassium oxide. Basalt has a certain resistance to acidity and may be weathered if exposed to acidic conditions for a long time.

Basalt has the characteristics of high hardness, high density, compression resistance, wear resistance, corrosion resistance, weak conductivity, durability, sound absorption and heat insulation, and is often widely used in the following fields.

Construction field: Because basalt has high density and high hardness, it is often used for decoration of building floors, exterior walls, roofs, etc. It not only improves the compression and bending resistance of the building, but also improves the overall stability and safety of the building.

Roads and bridges: Basalt has the advantages of strong hardness, high density and good durability. It is very suitable for road construction materials and can withstand the pressure of pedestrians and traffic in the flow. At the same time, bridges built with basalt have stronger weighing capacity and durability.

Landscape field: Basalt has a deep color and hard texture. It is often used as a ground material for streets, squares and venues in parks, gardens and urban landscapes.

Industrial field: Basalt can be used as raw materials for filters, dryers, catalysts, etc. After melt casting, crystallization, annealing and other processes, basalt can be made into hard and wear-resistant alloy steel with better corrosion resistance.

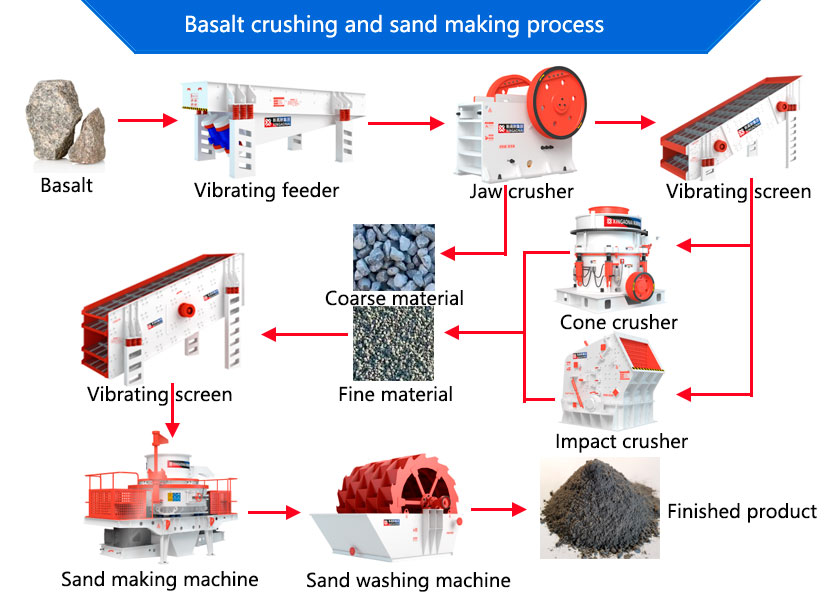

Common equipment for basalt crushing and sand making production line includes jaw crusher, cone crusher, impact crusher, impact crusher, vibrating screen, conveyor and other equipment.

First, the vibrating feeder evenly feeds the material into the jaw crusher for coarse crushing, and the coarsely crushed stone is sent to the cone crusher (or impact crusher) through the conveyor for fine crushing and shaping. After fine crushing, the material is sent to the vibrating screen for screening through a conveyor. The stone that meets the sand making requirements is sent to the sand making machine for sand making, and the material that does not meet the sand making requirements is returned to the secondary crushing equipment for re-crushing to ensure that the materials meet the sand making requirements. Finally, the finished sand from the sand making machine is sent to the sand washing machine for cleaning, and thus a basalt crushing and sand making production line is formed.

Article Title: Hardness, characteristics and applications of basalt

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Hardness-characteristics-and-applications-of-basalt.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap