Xingaonai

Xingaonai

Industrial aluminum profiles are also called industrial aluminum extrusions and industrial aluminum alloy profiles. They are alloy materials with aluminum as the main component. Aluminum alloys are obtained through hot melting, extrusion and other operations to obtain aluminum materials with different cross-sectional shapes. The performance and application fields of the produced aluminum alloy materials are different due to the different proportions of added alloys. Aluminum alloy materials are mainly composed of aluminum, magnesium, copper, silicon and other elements. Industrial aluminum alloy materials have the characteristics of corrosion resistance, good thermal conductivity and strong plasticity.

The density of aluminum is about 2.7 grams per square centimeter, which is lighter than other steels, which can reduce weight and improve work efficiency.

Aluminum is corrosion-resistant and can be used for a long time in a humid environment without being oxidized.

Aluminum also has very good thermal conductivity and can be used as a heat dissipation device to protect mechanical equipment.

Aluminum is relatively soft and can be made into various shapes of materials through extrusion, stretching and other methods, which is easy to process.

The manufacturing process and uses of aluminum alloy materials can be divided into the following categories:

Aluminum profiles: industrial aluminum alloy engineering profiles, industrial aluminum alloy power profiles, industrial aluminum alloy building profiles, etc.

Aluminum plates: industrial aluminum alloy electroplated plates, industrial aluminum alloy color-coated plates, industrial aluminum alloy galvanized plates, etc.

Aluminum bars: industrial aluminum alloy wires, industrial aluminum alloy bars, etc.

Aluminum foils: industrial aluminum alloy pharmaceutical packaging foils, industrial aluminum alloy jewelry packaging foils, etc.

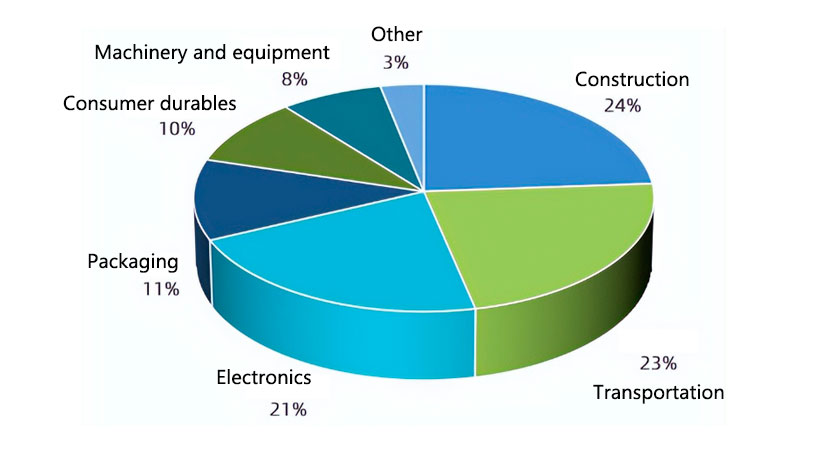

Construction industry: Aluminum alloys are widely used in the construction industry and can be used to make doors, windows, curtain walls, ceilings, etc. Compared with steel or copper, aluminum alloys have the characteristics of good strength, light weight, corrosion resistance, and easy processing. In addition, aluminum alloys have very good thermal conductivity and are also widely used in the field of building energy conservation.

Aerospace: Because aluminum has the characteristics of light weight, high strength, corrosion resistance and no rust, it plays an important role in the field of aerospace. Many key components in aerospace equipment are made of aluminum, such as fuselages, wings, etc.

Electronics and electrical: Because of its excellent thermal conductivity, low density, corrosion resistance and other superior characteristics, aluminum is also widely used in the field of electronics and electrical. It is mainly used to manufacture components such as housings, heat sinks, wiring equipment, etc. of electronic products. Aluminum has stable physical properties and remains unchanged in various working environments.

Transportation: Rails also have a very good position in the field of transportation. Cars made of aluminum are light in weight and fast in speed, which effectively reduces the energy consumption of the car and improves driving safety and comfort. In addition, aluminum can be used to make ship structures, making the hull corrosion-resistant and light in weight, and can better adapt to the marine environment.

Packaging: Aluminum is a recyclable metal material and can also be widely used in the packaging industry. Aluminum cans can keep food fresh and attract consumers better. Aluminum foil made of aluminum can be used to package kitchen supplies, medicines, cosmetics, etc.

In general, aluminum is a very magical metal element that has made great contributions to the construction, aerospace, electronics and electrical, transportation, packaging and other industries. Due to its advantages such as corrosion resistance and recyclability, it is believed that aluminum can play a major role in more industries.

Article Title: Do you know the uses of aluminum in industry?

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Do-you-know-the-uses-of-aluminum-in-industry.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap