Xingaonai

Xingaonai

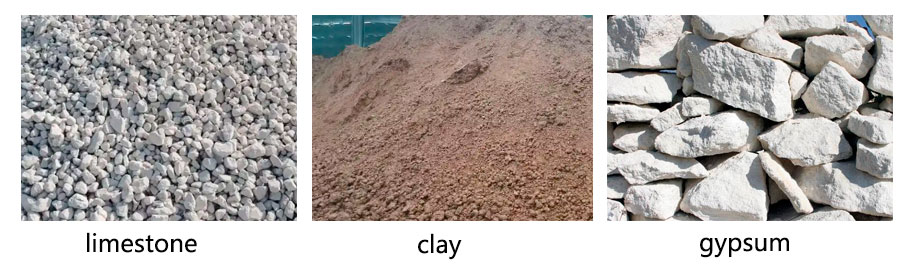

Cement is mainly composed of minerals such as clay, limestone, and gypsum. It is an important building material. The cement production process is relatively complicated. By adding other materials to adjust its chemical composition, such as sandstone, iron ore, bauxite, etc. in the raw materials, it can effectively strengthen the building and enhance the durability of the building.

Limestone: A mineral containing a large amount of calcium, mainly composed of calcium carbonate. Each ton of limestone contains about 720 kilograms of calcium. It is one of the main raw materials for cement.

Clay: Clay, a powdery substance composed of elements such as silicate, iron, magnesium, potassium, and sodium, is also one of the main raw materials for cement.

Gypsum: In the process of cement production, in order to control the setting reaction and hardening time of cement, a certain amount of gypsum is added to make the cement have a certain ductility and durability.

Iron ore: The color and characteristics of cement can be adjusted by adding iron oxide.

Cement is an inorganic substance, mainly made by thermal reaction of limestone, clay and other substances. Under high temperature conditions, clay and limestone react fully to produce new compounds, which form solidified cement after cooling, and are ground into powder to form cement.

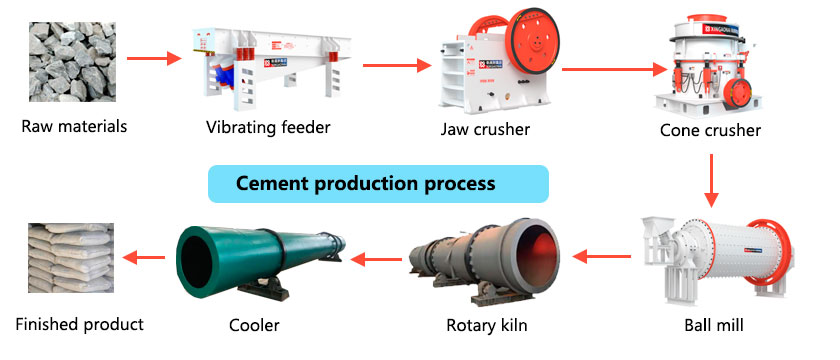

Crushing: Use a crusher to crush cement production raw materials such as limestone, clay, iron ore and coal, and use scientific technology to preliminarily homogenize the raw materials during the storage and retrieval of raw materials.

Grinding: Using a ball mill for grinding, optimizing process parameters, and correctly controlling the operating system are of great significance to reducing energy consumption and ensuring product quality.

Mixing: After the ground materials, add an appropriate amount of gypsum to the calcined materials and mix them evenly to form raw materials.

Decomposition: It should include steps such as material dispersion, gas-solid separation, and pre-decomposition.

Calcination: In the rotary kiln, carbonates are rapidly decomposed and solid-phase reactions occur to generate minerals in cement clinker.

Grinding: Grind the cement clinker to a suitable mesh size, reach a certain number of particles, increase the accelerated hydration rate, and meet the requirements of cement slurry hardening and coagulation.

Packaging: The finely ground cement powder is packed into bags or bulk trucks for storage and transportation.

According to the properties and uses of cement, it can be divided into the following types:

Ordinary Portland Cement: Made by calcining a mixture of limestone and clay, stored in a cool, dry warehouse away from humidity and direct sunlight, suitable for most construction projects.

Lightweight Cement: A lightweight building material made of cement, lightweight aggregates and a certain amount of additives as raw materials, through mixing, pouring, curing and other process steps, suitable for lightweight concrete and thermal insulation materials, etc.

High-strength Cement: It uses special raw materials and production processes to improve its mechanical properties and crack resistance, and is suitable for projects that require high-strength building structures.

Refractory Cement: It can maintain strength and stability under high temperature conditions. It is mainly composed of refractory materials and an appropriate amount of cementitious materials.

Cement is widely used in the construction field, such as concrete production, mortar, foundation consolidation, walling, cement products, etc. Cement has good compressive strength and plasticity, and is widely used in the construction of infrastructure such as roads and bridges.

In short, cement is a common building material made of limestone, clay and other materials. Its production process requires multiple steps, including crushing, grinding, mixing, decomposition, calcination, grinding and packaging. Different types of cement have different uses and properties, and the type of cement is selected according to needs. In addition, cement production may have a certain impact on the environment, and attention should be paid to environmental protection.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Do-you-know-how-cement-is-made.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap