Xingaonai

Xingaonai

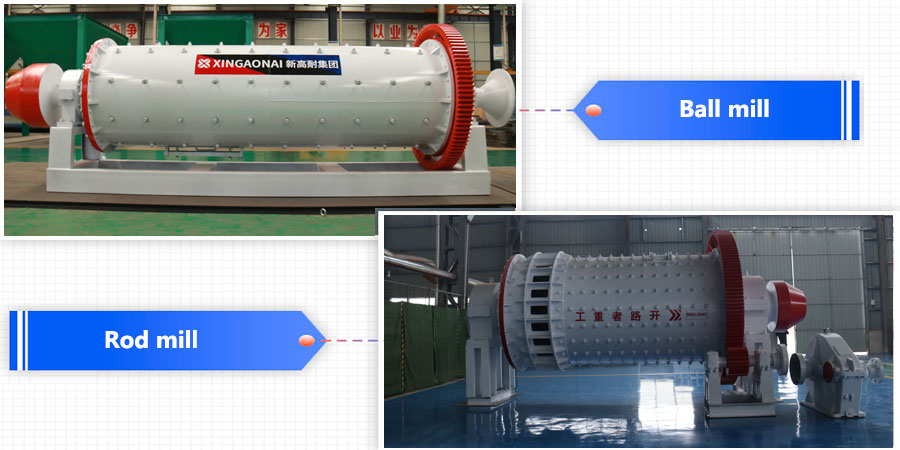

Ball mills and rod mills are both common ore dressing and grinding equipment, widely used in ore, building materials, chemical and other industries. Although the appearance and principle are similar, there are many differences in structure, performance, use, etc. They each have unique characteristics and scope of application. Choosing the right grinding equipment is crucial to improving production efficiency, reducing energy consumption and optimizing product quality. Below, New High-Resistance Heavy Industry will analyze the differences between them.

The grinding medium of the ball mill is steel balls. After ore, stone and other materials enter the ball mill, they roll, rub and collide in the rotating grinding cylinder to grind the materials. Inside the ball mill, the materials are ground due to friction and collision in the grinding cylinder, and finally reach the required particle size.

The grinding medium of the rod mill is steel rods. After the materials enter the rod mill, they are subjected to friction, collision and grinding in the rotating cylinder to grind the materials. Compared with the ball mill, the grinding effect of the rod mill is mainly achieved through the friction grinding between the rod mill and the materials.

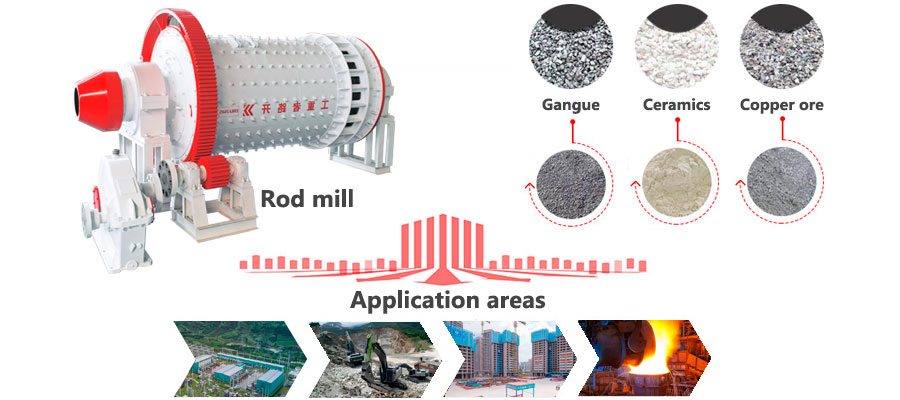

Ball mills are suitable for grinding various ores and other materials. They are widely used in mineral processing, building materials and chemical industries. In addition, both can grind materials dry and wet.

Compared with ball mills, rod mills use advanced controllable feeding and discharging technology, and can use suitable grinding bodies according to the grinding materials. The point contact of traditional ball mills is changed to line contact, which can make the discharge particle size more uniform and the output higher. It is mainly used for the re-selection or magnetic separation of tungsten tin ore and other rare metal ores, because the use of rod mills can prevent dust pollution caused by excessive crushing and improve the recovery rate of sorting operations.

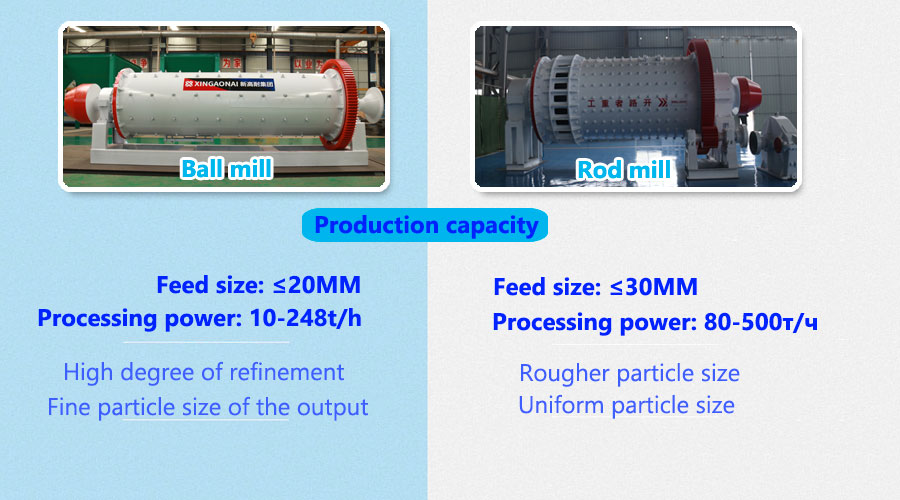

There are also certain differences in production capacity between ball mills and rod mills. The performance characteristics of ball mills are high production capacity, strong adaptability to materials, high material fineness, fine discharge particle size, easy fine grinding, and significant energy saving, but its over-crushing phenomenon is serious. The process characteristics of the rod mill are that the product is relatively rough, but the particle size is uniform, it contains less coarse particles and ore mud, the over-crushing phenomenon is relatively light, and the particle size characteristics of the rod mill product are related to the situation of the rod mill crushing ore.

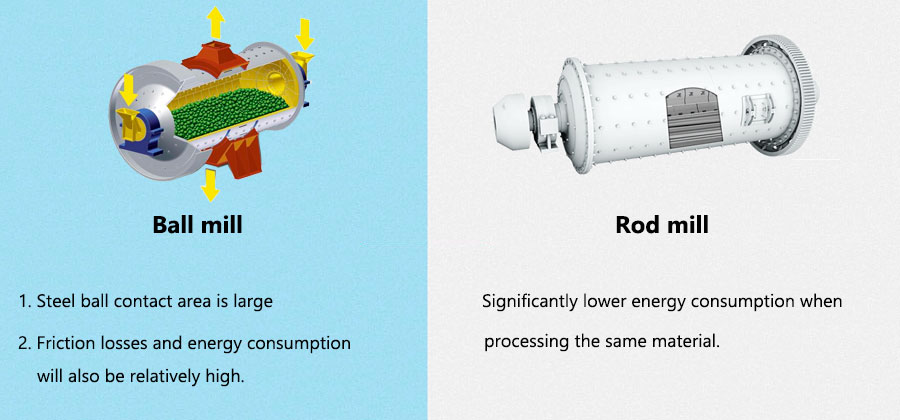

There are also differences in energy consumption between ball mills and rod mills. Since the ball mill uses steel balls, the contact area between the steel balls is large, so the friction loss and energy consumption will also be relatively high. Compared with the ball mill, the rod mill can significantly reduce energy consumption when processing the same material, and is especially suitable for energy-sensitive ore processing. When selecting equipment, if there are strict requirements on energy consumption during the production process, the rod mill may be a more suitable choice.

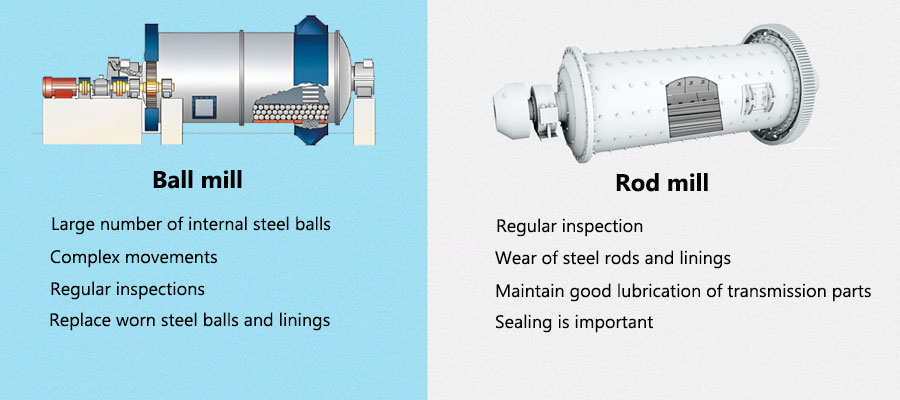

There are also certain differences in maintenance and care between ball mills and rod mills. Due to the large number of internal steel balls and complex movements, the ball mill needs to regularly check and replace worn steel balls and liners to ensure grinding efficiency and equipment life. The sealing and lubrication system of the ball mill also need special attention to prevent oil leakage and dust pollution.

Rod mill maintenance is relatively simple. The main work includes regular inspection of the wear of steel rods and linings, and keeping the transmission parts well lubricated. The sealing of the rod mill is also the focus of maintenance to prevent the dust generated during the grinding process from leaking out and affecting the working environment and personnel health.

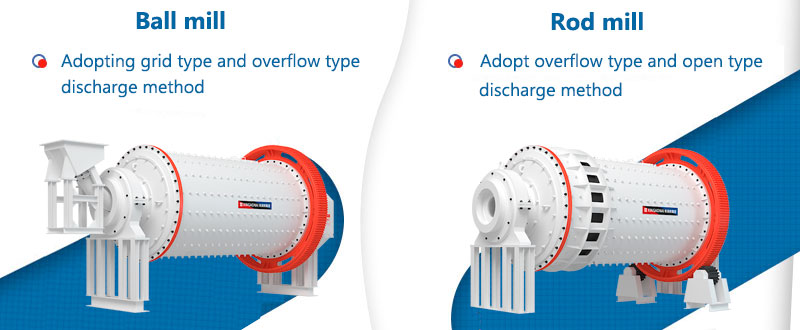

The commonly used ball mills are grate type ball mills and overflow type ball mills, which use grate type and overflow type discharge methods respectively. Rod mills do not use grate plates for discharge, but only overflow type and open type. The diameter of the hollow shaft at the discharge end is generally larger than that of ball mills of the same specifications.

There are also certain differences in the prices of ball mills and rod mills. Generally speaking, the price of ball mills is relatively low, which is more suitable for small and medium-sized enterprises; the price of rod mills is relatively high, which is more suitable for large enterprises.

In summary, the scientific and reasonable selection of ball mills and rod mills requires comprehensive consideration of the working principle, application range, production capacity, energy consumption, maintenance and maintenance, discharge method, price and other aspects. When selecting a model, you should comprehensively consider the characteristics of the materials to be ground, production requirements, energy consumption, maintenance and other aspects to choose the grinding equipment that suits you.

If you want to know more about the crusher, please call or consult online or leave a message. Xin Gaonai Heavy Industry will send professionals to answer your questions.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Difference-between-ball-mill-and-rod-mill.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap