Cone Crusher Spare Parts Detailed Explanation and Sales

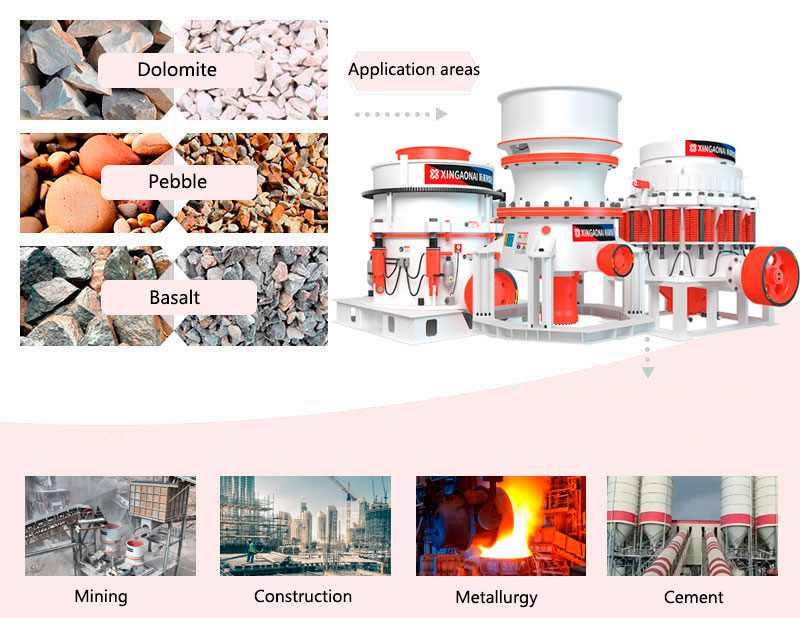

Cone crusher is a commonly used mining crushing equipment with high efficiency, low energy consumption and good quality. It is suitable for materials with high hardness and is widely used in mining, metallurgy, chemical industry and other industries. Due to the harsh use environment and large dust of cone crusher, and the inadequate maintenance of some enterprises, the quality requirements of accessories are high, but some wearing parts will be replaced frequently. So, do you know what wearing parts are there in cone crusher? What are the functions of these wearing parts? Let's explain them in detail.

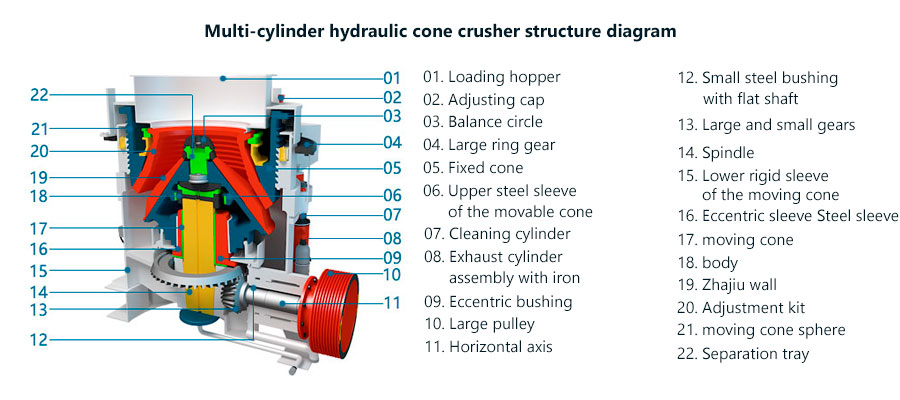

Composition and working principle

The cone crusher is mainly composed of frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), hydraulic coupling, lubrication system, hydraulic system, control system and other parts.

The moving cone is driven by the transmission device to rotate and swing under the action of the eccentric sleeve, and the moving cone and the static cone are squeezed and impacted many times to crush the material. The materials that meet the requirements are discharged from the bottom of the cone under the action of gravity.

Cone crusher vulnerable parts

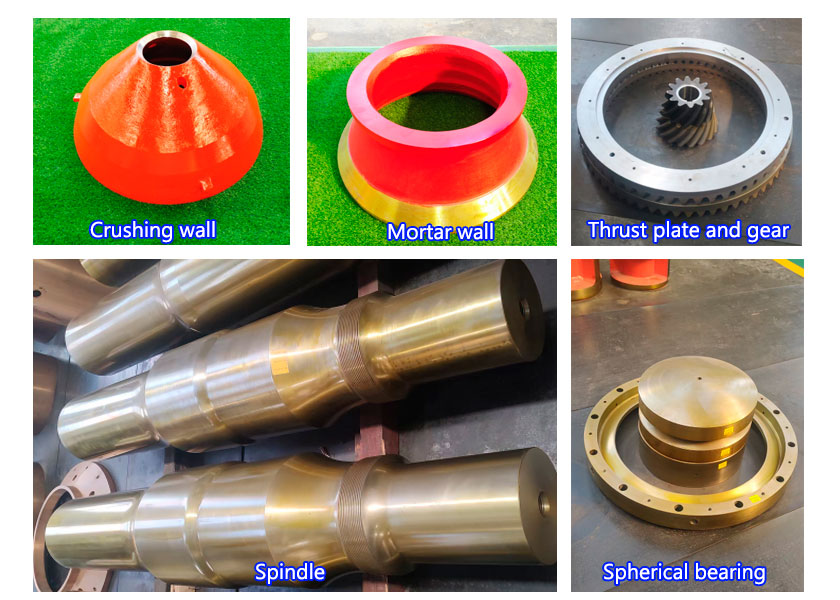

The vulnerable parts of cone crusher include crushing chamber, crushing wall, rolling mortar wall, main shaft and cone bushing, thrust plate and gear, frame and spherical bearing, eccentric sleeve and straight sleeve, sleeve, cone sleeve, etc. So what are the functions of these vulnerable parts? Let's analyze it now.

Crushing chamber

The parallel area of the crushing chamber is seriously worn. At the same time, when the fixed cone entrance and the moving cone liner are both worn, the wear of the entire parallel area will be greater than the wear of the upper chamber. After the crushing chamber is worn, the cavity shape completely loses its original shape, which seriously affects the crushing effect of the crusher.

Crushing wall

The crushing wall is fixed on the cone body, and zinc alloy is cast between them. The crushing wall is the key to crushing materials. Damage will cause downtime. After replacement, the fastening should be checked, and if loose, it should be tightened immediately.

Rolling mortar wall

The crushing wall and rolling mortar wall are the main wear-resistant parts in the cone crusher, and are also the parts that directly crush materials.

When replacing the mortar wall, the adjusting screw sleeve should be unscrewed counterclockwise, and then the upper chamber hopper assembly can be removed to replace the mortar wall. When installing, clean the surface first, then apply butter on the adjusting screw sleeve thread, and then install it in the reverse order of disassembly.

Spindle and cone bushing

Under normal working conditions of the crusher, if the main shaft and cone bushing are worn more heavily at the bottom and lighter at the top, the moving cone will have a slight instability phenomenon, and the crusher cannot operate normally. If the main shaft and cone bushing are partially in contact at the lower end, the cone bushing will crack and damage.

Thrust plate and gear

The thrust plate wears more severely along the outer circle. Due to the high linear speed of the outer ring, the wear is faster than the inner ring. The skewness of the eccentric sleeve also aggravates its outer ring wear. When the crusher is running, the large bevel gear moves around the crusher with a radius of the straight bushing gap. This will cause additional impact vibration and additional wear on the gear during operation, shortening the gear life.

Spherical bearing

The spherical bearing is also a wear part. When the moving cone loses stability and the main shaft is stuck at the lower end of the cone bushing, the lower end of the cone bushing will crack and be damaged, resulting in the "flying car" phenomenon and damage to the spherical bearing, which should be replaced in time.

Eccentric sleeve and straight sleeve

The wear of the eccentric sleeve is manifested in the height direction of the eccentric sleeve, with heavy wear on the upper part and slight wear on the lower end. The degree of wear on the upper part is also gradually reduced from top to bottom. During the operation of the cone crusher, the straight sleeve often moves upward and cracks appear on the straight sleeve. It is easier to cause cracks after the straight sleeve moves upward, but when the straight sleeve cracks, the debris produced will cut the surface of the center hole of the frame, making it out of round; the crack debris is particularly serious for the eccentric sleeve, which will deteriorate the working condition of the whole machine and even cause serious accidents.

Sleeve

When the sleeve is worn to a certain extent, it must be replaced in time, otherwise it will seriously affect production. Replacing the sleeve also requires certain skills. When removing the sleeve, you should choose the cutting ring that separates the sleeve to prevent damage to the main shaft. Then you can easily remove the sleeve by rotating it counterclockwise with an iron rod.

Cone sleeve

The cone sleeve should be checked and replaced regularly. The replacement cycle should be determined according to the hardness of the material processing and the daily working hours. When replacing, zinc alloy should be added to prevent the sleeve from rotating. There should be no gap between the cone crusher sleeve and the eccentric shaft.

The above is a detailed explanation of the consumable parts of the cone crusher. In addition, the crushing wall and the rolling mortar wall are important parts of the cone crusher and are also consumable parts that are replaced frequently. When the equipment is running, it is strictly forbidden to enter the crushing chamber with materials that are too hard or too high in moisture, otherwise it may cause the crushing wall, rolling mortar wall, and equipment shutdown.

Xingaonai Heavy Industry has the best quality cone crusher spare parts, and its price is the most cost-effective among its peers. If you need cone crusher consumable parts, please contact our customer service, and we will deliver them to you by air at the fastest speed.

Article Title: Cone Crusher Spare Parts Detailed Explanation and Sales

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Cone-Crusher-Spare-Parts-Detailed-Explanation-and-Sales.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222