Xingaonai

Xingaonai

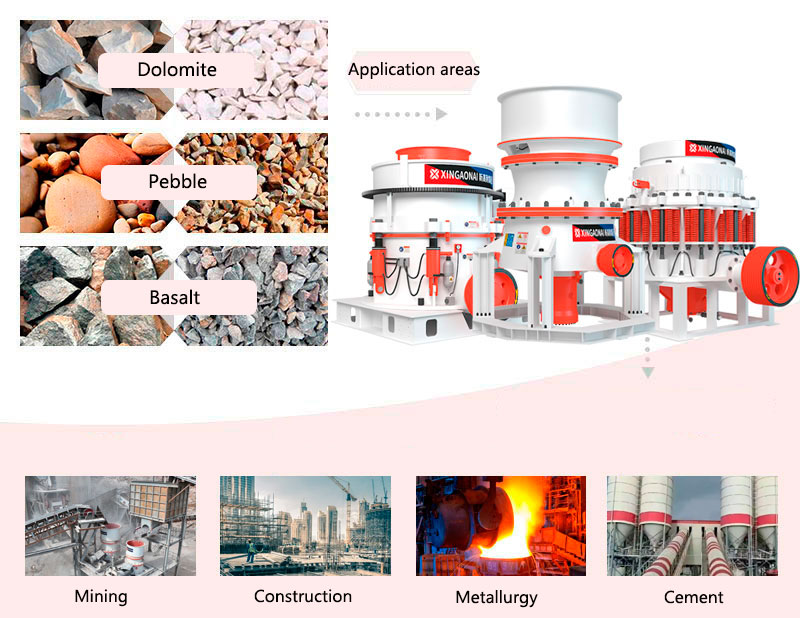

Cone crusher is a very common mining crushing equipment. The crushing chamber is conical and is mainly used for crushing various ores of medium hardness and above. It adopts the extrusion crushing principle of the conical crushing chamber, with high crushing efficiency, large processing capacity, convenient operation, and low later maintenance cost. It is widely used in metallurgy, construction, mining, chemical industry and other industries. Below, New High-end Heavy Industry will introduce in detail the classification, advantages and application fields of cone crushers.

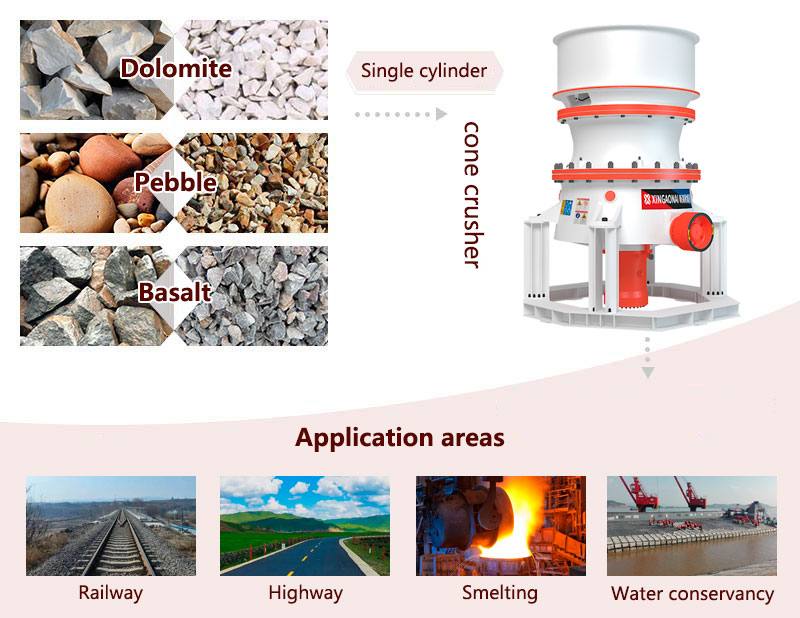

Single cylinder hydraulic cone crusher

Single-cylinder hydraulic cone crusher is a high-efficiency crusher designed in combination with the performance of metal materials. The unique bottom single-cylinder design realizes functions such as direct adjustment of the discharge port, iron prevention, and cleaning of the cavity. It is mainly composed of upper frame, fixed cone, lower frame, eccentric sleeve, main shaft motor cone, bottom hydraulic cylinder, etc.

Multi-cylinder hydraulic cone crusher

Multi-cylinder hydraulic cone crusher is designed on the basis of spring cone crusher, and its basic structure is similar to that of spring cone crusher. It is a typical crushing equipment for medium and fine crushing of hard materials. It also has multiple nitrogen cylinders with one-to-one hydraulic cylinders, and adopts PLC+touch screen automatic control system, which is smarter than other cone crushers. It is mainly composed of fixed cone, moving cone, eccentric sleeve, transmission, frame, locking protection cylinder, hydraulic station and other components.

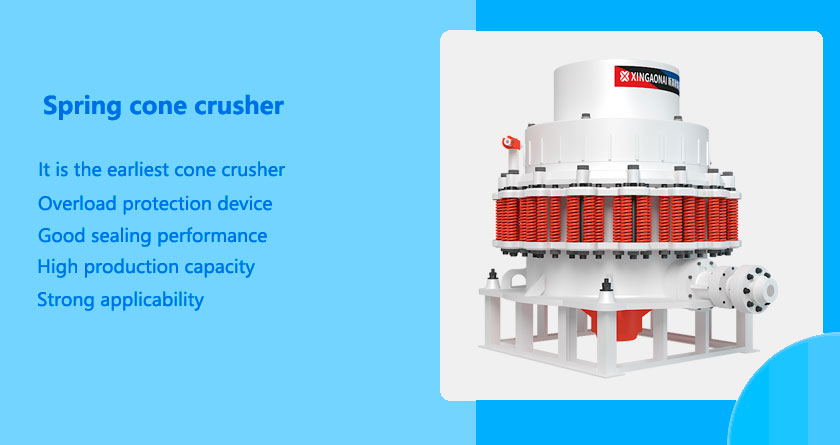

The perfect combination of high crushing frequency and high-performance crushing chamber greatly improves the crushing capacity. The laminated crushing principle reduces needle-like materials. It is also equipped with an overload protection device to provide iron release protection for particularly hard foreign objects such as iron blocks, achieving a 95% equipment failure-free operation rate. It is mainly composed of a frame, transmission device, empty eccentric shaft, bowl-shaped bearing, crushing cone, adjustment device, adjustment sleeve, spring and other parts.

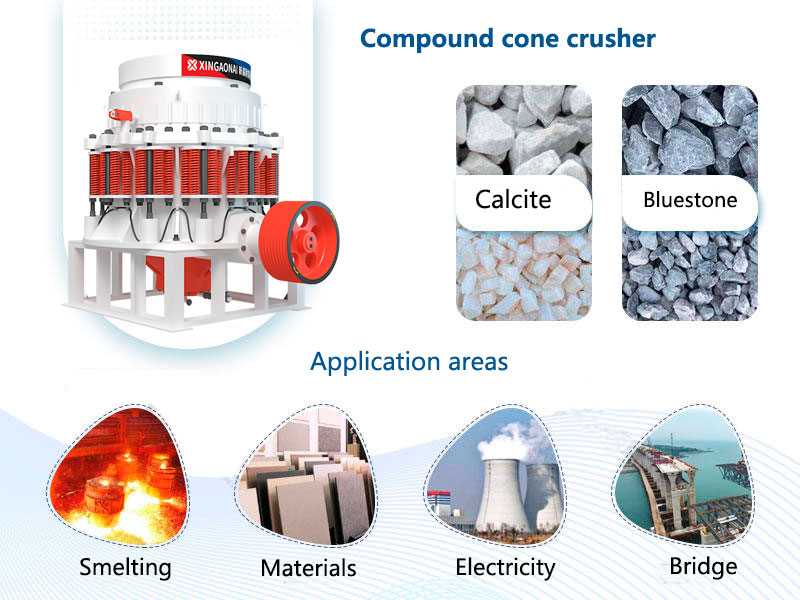

The compound cone crusher is a new type of crusher designed by combining the advantages of spring cone crusher and hydraulic cone crusher. It can crush medium and above materials, and has the characteristics of large crushing ratio, high efficiency, high processing capacity, low operating cost, convenient adjustment, and economical use.

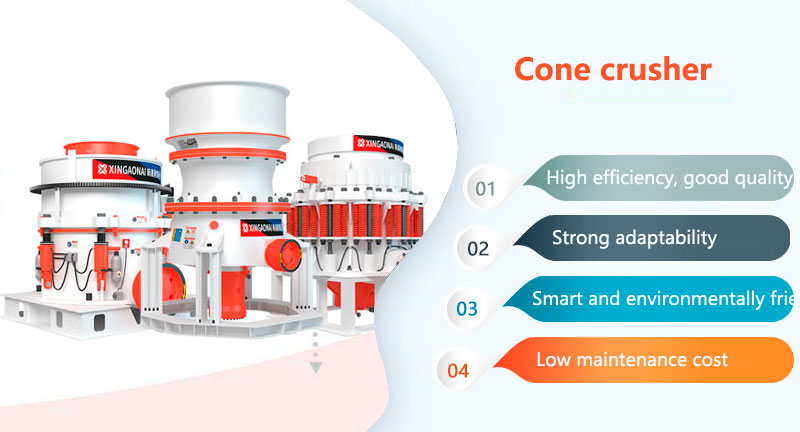

High production efficiency: The design of continuous rotation of the moving cone is adopted, and the crushing and unloading of materials are carried out alternately and continuously, thus achieving efficient production.

Uniform particle size and high quality: The special crushing chamber design and matching rotation speed make the crushed materials in a cubic shape and uniform particle size. This design increases the proportion of fine materials and the content of cubes, effectively improving the product quality.

Strong adaptability: Adjust the equipment parameters to meet the crushing requirements of different materials, and show strong adaptability when crushing materials of different hardness.

Intelligent and environmentally friendly: The cone crusher is equipped with a remote operating system, which can be remotely operated through a remote touch device. The real-time working status of the equipment is displayed on the interface, which can be monitored and adjusted in real time. At the same time, the design also takes into account energy-saving and environmental protection factors, effectively reducing energy consumption and noise pollution.

Low operating cost and easy maintenance: The cone crusher has a reasonable structural design, stable operation, and few wearing parts, which makes the later maintenance simple and greatly reduces the operating cost. At the same time, a thin oil lubrication system is adopted to effectively increase the service life of the equipment.

1. Mining industry: mainly used for medium and fine crushing of ores, and also suitable for crushing ores of different hardness and different water content, such as limestone, granite, sandstone, etc.

2. Metallurgical industry: can be used to process various non-ferrous metal ores such as silver, gold, copper, high-hardness minerals, limestone and other materials.

3. Construction industry: can be used to crush hard materials such as high-strength concrete, basalt, granite, etc., and is widely used in the construction industry, such as highways, railways, water conservancy projects and other infrastructure.

4. Cement industry: can be used to process raw materials, clinker, coal powder, cement clinker, glass and other materials, and plays a major role in the cement industry.

Article Title: Classification and application advantages of cone crusher

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/Classification-and-application-advantages-of-cone-crusher.html

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: sales@xgnchina.com

Whatsapp: 8617761642222

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap