Xingaonai

Xingaonai

Quartz sand is a sedimentary rock, igneous rock, etc. composed of clastic quartz particles. It is an important non-metallic mineral resource, widely distributed in the earth's crust, and has a wide range of application value. Understanding the main chemical components of quartz sand can better understand its characteristics and application areas.

The main chemical components of quartz sand include silicon dioxide (SiO2), aluminum oxide (Al2O3), iron oxide (Fe2O3) and potassium oxide (K2O). Among them, the silicon dioxide content is the highest, generally reaching more than 95%, the aluminum oxide content is generally between 1-3%, and the iron oxide and potassium oxide content are relatively low.

High hardness: The hardness of quartz sand is 7, ranking 7th among minerals, second only to diamonds, molybdenum and very few other minerals. Therefore, quartz sand has high wear resistance and durability.

High temperature resistance: Quartz sand can withstand high temperatures, and its melting point is as high as 1713 degrees Celsius, so it can remain stable when used in high temperature environments.

Chemical stability: Quartz sand has stable chemical properties and does not react chemically in most acid and alkali solutions. Therefore, it is widely used in the manufacture of chemical containers or as a catalyst carrier in the chemical industry.

Low density: The density of quartz sand is 2.65 g/cm3, which is more than twice that of ordinary sand. Therefore, it is widely used in steel, aviation and other industries.

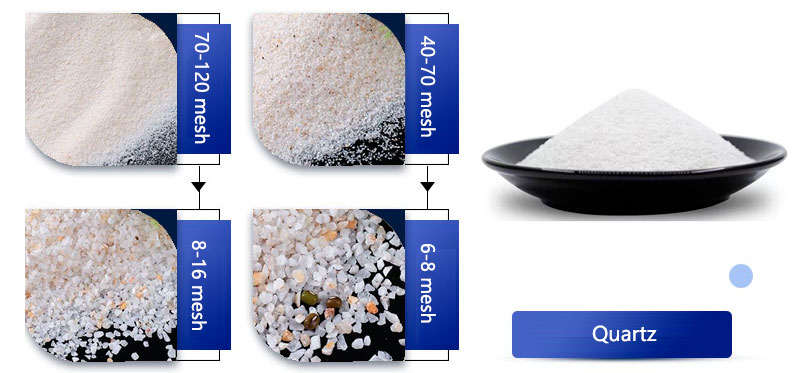

Quartz sand is generally divided into ordinary quartz sand and high-purity quartz sand. It is widely used in various fields for its high purity and stability.

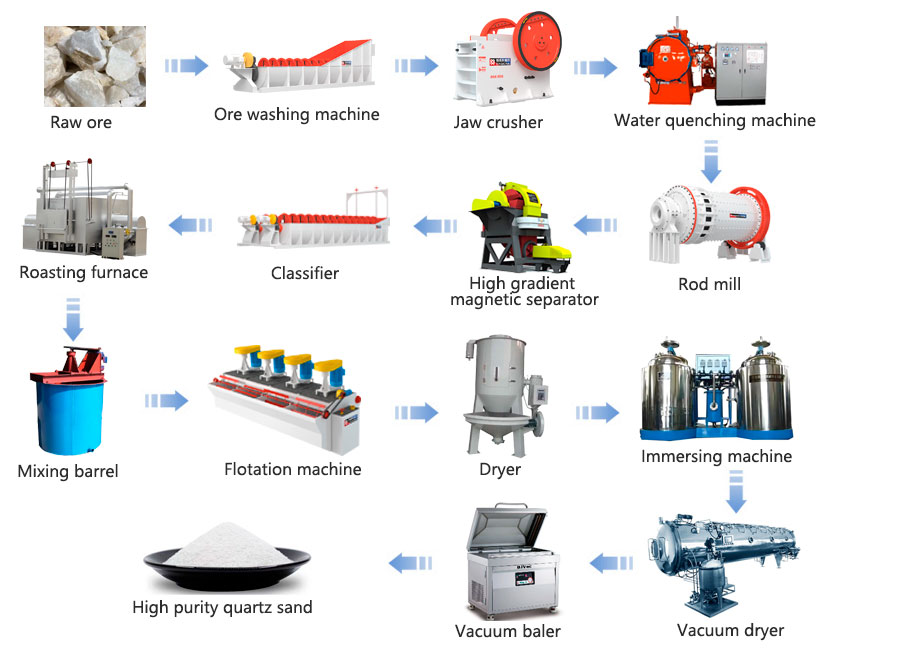

Ordinary quartz sand process flow

Ordinary quartz sand: SiO2 content is between 90% and 99%, refractoriness is 1750℃, the appearance is partially large particles, and there are yellow capsules on the surface. Ordinary quartz sand is generally a water treatment filter material made of natural quartz ore after crushing, washing, drying, and secondary screening; the filter material has the characteristics of no impurities, no correction angle, high density, high mechanical strength, pollution carrying capacity and long service life, and is an ideal material for chemical water treatment. The particle size range is 5-220 mesh, and it can be produced according to the particle size required by the user.

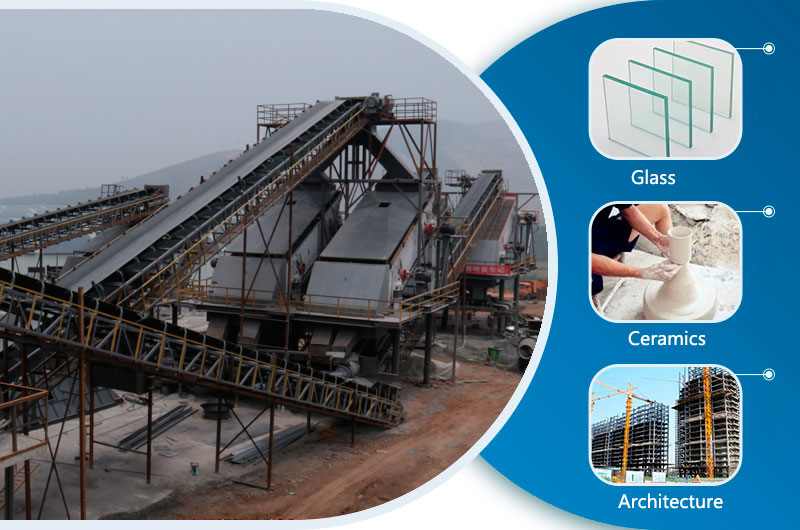

Main uses: metallurgy, ink silicon carbide, glass and glass products, enamel, cast steel, water filtration, sodium silicate, chemical industry, spraying and other industries.

High purity quartz sand process flow

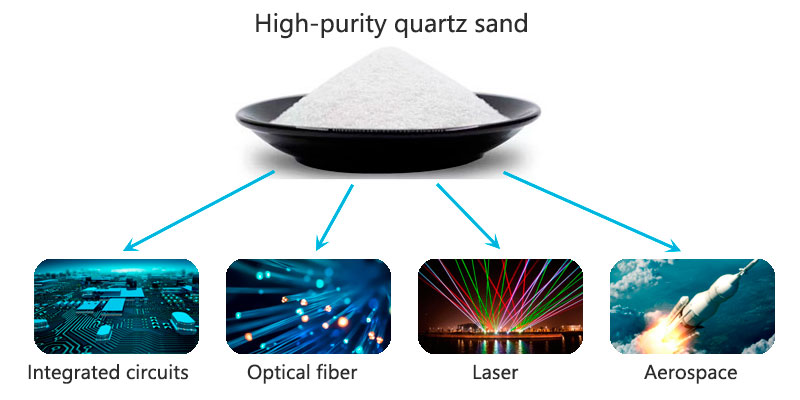

High-purity quartz sand: quartz powder with SiO2 content higher than 99.9%, mainly used in IC integrated circuits and quartz glass industries, and its high-end products are widely used in large-scale and ultra-large-scale integrated circuits, optical fibers, lasers, aerospace, and military. High-purity quartz sand is a neutral inorganic filler that does not contain crystal water and does not participate in the chemical reaction of the filled material. It is a very stable mineral filler and is widely used in plastics, rubber, ceramics and coatings. It can not only add various new functions to the product, but also save a lot of raw materials.

The main process flow of high-purity quartz sand is as follows: the original silica ore is washed by a ore washer to remove the sand and mud, and after the crusher is roughly broken, the qualified quartz material is put into the roasting furnace and roasted at 850℃~980℃ for 6 hours. After roasting, the quartz material is dragged into clean water for water quenching, and then manually sorted to remove impurities and sent to the crusher for crushing and sieving. The quartz sand that passes through the screen is then sent to the magnetic separator. After magnetic separation, the quartz sand is put into an acid tank equipped with HCl and HF mixed acid and soaked for one week, and then flotation, dehydration, baking, cooling, and packaging are carried out to obtain high-purity quartz sand.

Summary: Quartz sand is a mineral resource widely used in life. Its main component is silicon dioxide, which has the characteristics of high purity and stability. It has a wide range of application value in industrial fields such as glass, ceramics, electronics, and construction.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/783.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap