Xingaonai

Xingaonai

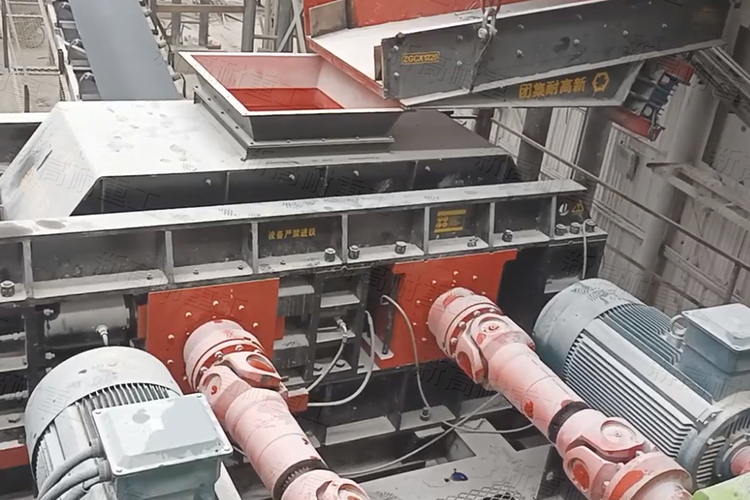

As a common non-metallic mineral resource, limestone is widely used in many fields such as building materials, chemical industry, and metallurgy. The double-roller sand making machine, also known as the double-roller sand making machine, is suitable for the crushing of medium-hardness and brittle materials, especially for limestone, which is a medium-hardness and brittle mineral. The double-roller sand making machine can show its unique advantages.

Productivity consideration

The production capacity of the double-roller sand making machine is mainly affected by the following factors:

1. Equipment specifications: There are differences in the production capacity of different types of double-roller sand making machines, and the production capacity of large-scale equipment is naturally higher.

2. Material characteristics: The hardness, water content, and feed particle size of limestone will affect the production capacity. Limestone with higher hardness or higher water content will reduce the crushing efficiency of the equipment.

3. Equipment design and maintenance: The internal design of the equipment, such as the size, shape, surface material, and wear degree of the roller, will affect the quality and efficiency of the sand output, and regular maintenance and appropriate adjustments can ensure the best operating state of the equipment.

4. Operating conditions: How to control the feed speed, whether the feed is evenly fed, and the operation mode of the equipment directly affect the production capacity and sand production rate, and correct operation can optimize the equipment performance and improve efficiency.

5. Finished product requirements: The particle size requirements for the finished sand will also affect the production capacity. If a finer particle size is required, finer crushing may be required, which may reduce the sand production rate.

Analysis of sand production rate

The sand production rate refers to the proportion of finished sand that meets the specific particle size requirements after being processed by the double-roll sand making machine. This proportion is an important indicator for measuring the performance of the double-roll sand making machine, because the sand production rate directly affects the efficiency and economic benefits of the production line. The following are some key analysis points of the sand production rate of the double-roll sand making machine:

1. Material moisture: Limestone with high moisture content will reduce the sand production rate, because moisture may cause material adhesion and affect crushing efficiency.

2. Material viscosity: Materials with high viscosity are more likely to stick to the inside of the crushing chamber, thereby affecting crushing efficiency and sand production rate.

3. Material particle size: The size of the raw material particle size will also affect the sand production rate. Usually, a smaller feed particle size helps to improve the sand production rate, while an oversized particle size

3. Roller material: The wear resistance and hardness of rollers of different materials will affect the crushing effect, and then affect the sand production rate. Choosing the right material can improve the sand production rate.

4. Roller spacing: The spacing determines the particle size of the material. Although a too small spacing can obtain finer sand, it may reduce the sand production rate.

5. Equipment performance: The linear speed, rotation speed and other parameters of the equipment affect the crushing efficiency and sand production rate of the material.

In summary, in actual production, to improve the production capacity and sand production rate of the double-roller sand making machine, it is necessary to comprehensively consider and adjust according to the above factors. For example, select suitable materials, optimize equipment parameters, improve operating procedures, strengthen equipment maintenance... Through scientific management and reasonable adjustment, the efficiency of the double-roller sand making machine can be maximized and the ideal sand production rate can be achieved.

Xin Gao Nai Zhong Gong, as a large domestic manufacturer of sand and gravel crushing equipment, has very mature crushing production technology and rich production experience. Its double-roller sand making machine has a complete range of models and a wide range of production capacity. Depending on the size of the machine, the processing capacity per hour can range from tens of tons to hundreds of tons, which can meet the needs of limestone processing production lines of different sizes. As for the sand output rate, its optimized crushing cavity type and reasonable roller surface structure design can directly produce sand with beautiful sand shape and high sand formation rate, which can effectively help users improve the quality and market competitiveness of products. In addition, its compact structural design, small footprint, and suitable for a variety of site layouts are ideal equipment for efficient conversion of limestone resources. The double-roller sand making machine produced by Xin Gao Nai Zhong Gong not only has good quality and performance advantages, but also has an affordable price positioning, which can fully guarantee the greater interests of users. If you have relevant needs, please feel free to inquire!

Author:[Xingaonai]

From February 24 to March 31, 2025, Xingaonai Heavy Industry will hold a large-scale promotion with the lowest price of the year.

Tel: +86 17761642222

Email: [email protected]

Whatsapp: 8617761642222

Article Title: What is the capacity and sand output rate of the double roller sand making machine for processing limestone?

Reprint URL: https://www.xgncrusher.com/Industralnews/668.html

Our products have been exported to over 170 countries in Africa, Asia, South America, Europe, etc.We are here to prodvide better products and service for you.

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap