Xingaonai

Xingaonai

Construction industry

Building gypsum and high-strength building gypsum (cementitious material)

Building gypsum is mostly used for building plastering, painting, masonry mortar and manufacturing various gypsum products; high-strength building gypsum is mainly used for plastering projects, decorative products and gypsum boards with higher requirements; high-strength building gypsum can also be made into high-strength waterproof gypsum by adding waterproofing agent; adding organic adhesive materials such as polyvinyl alcohol solution or synthetic resin emulsion can be made into non-shrinkage adhesive.

Example: Organic adhesive materials are compounded, and then combined with appropriate amounts of chemical admixtures such as retarders and water retainers to make interior wall painting gypsum; manufacturing wall materials such as gypsum blocks and paper-faced gypsum boards and decorative structures such as gypsum lines and gypsum reliefs.

Gypsum for flooring materials

Natural dihydrate gypsum is calcined at above 800℃ to decompose calcium oxide from part of calcium sulfate. The ground product is called high-temperature calcined gypsum, also known as floor gypsum. This type of gypsum has high strength and wear resistance after hardening, and good water resistance. It can be used as gypsum floor and gypsum cushion, etc.

Examples: gypsum floor materials, self-leveling gypsum floor materials.

Interior wall putty and functional putty

Using gypsum cementitious materials as the main film-forming material, adding water-retaining agents, retarders, organic adhesives and other additives and fillers, ordinary interior wall putty and interior wall painting materials can be made; adding functional additives can make functional interior wall putty.

Examples: such as ordinary gypsum-based interior wall putty, negative ion-releasing interior wall putty, interior wall moisture-adjusting putty and interior wall painting materials, etc.

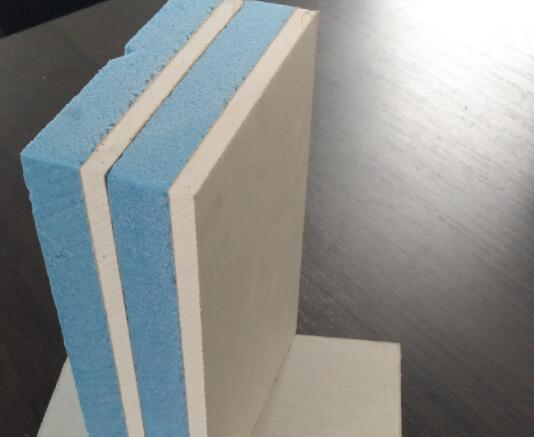

Fireproof materials

When encountering fire, the crystal water in dihydrate gypsum evaporates, absorbs heat, and forms anhydrous gypsum with good insulation and certain fire resistance on the surface of the product.

Examples: gypsum fireproof board, gypsum fireproof plugging material, etc.

Building materials industry

Cement additives

Gypsum plays a retarding role in cement, and can also improve the strength, shrinkage and corrosion resistance of cement. Generally, 3% to 5% of gypsum needs to be added to general cement to adjust the setting time.

Examples: As a retarder, mineralizer and other additives in the cement industry; as a raw material to produce special cement.

As an additive or active stimulant

The stimulating effect of gypsum on fly ash depends on two factors: the self-activity of calcined gypsum and the effect of stimulating fly ash. Type II calcined gypsum is the depolymerization effect of active CaO on the fly ash glass network in the early stage, and the sulfate stimulating effect of SO42- produced by the slow dissolution of CaSO4 with a relaxed structure in the later stage. When the alkalinity is high, Al3+ cross-links with [SiO2] in the form of [AlO4], accelerating the formation of C-S-H in the cementitious material, thereby improving the strength.

Example: The product of calcining gypsum at 1200-1280℃ is active CaO and structurally relaxed type II calcined gypsum. Type II calcined gypsum can be used as an activator for fly ash, slag, silicate cement and ash-based silicate building products to stimulate the activity of such materials and improve their strength.

Chemical industry

Production of sulfuric acid and cement

The CaSO4 in gypsum is decomposed into CaO and SO2 under the reduction of coke. The former is used to make cement clinker with clay raw materials, and the latter is used to make sulfuric acid. The chemical reaction formula is:

2CaSO4+C→2CaO+2SO2+CO2↑ (the reaction is carried out at 900-1350℃). A certain ratio must be maintained between CaSO4 and coke, and the ingredients are generally controlled by the C/SO3 (molar ratio) index. If C/SO3 is too low, that is, the amount of coke is insufficient, CaSO4 cannot be completely decomposed; if C/SO3 is too high, a side reaction will occur, causing part of the sulfur to form H2S or elemental S and be lost.

Fertilizer production

Ammonium sulfate (commonly known as ammonium sulfate) is a quick-acting nitrogen fertilizer, which is obtained by passing ammonia and carbon dioxide into a gypsum suspension.

Medicine and medical treatment

Plaster bandages, fixtures, etc.

After gypsum is mixed with water into a slurry, it has plasticity, and it sets and hardens quickly, increases in strength quickly, and has the strength required to maintain rigidity. For example, if the leg or arm is fractured, it can be fixed with a plaster bandage after the fracture, which can ensure that the bone is not dislocated.

Examples: plaster bandages for fractured limbs, "vegetative" fixtures, etc.

Chinese medicine

Gypsum tastes spicy and slightly cold. Spicy can relieve muscle heat, and cold can overcome stomach fire; spicy can go outside, and cold can sink inside. It has the function of both good at inside and outside.

Example: Heat-clearing and fire-purging medicine, mainly used to treat high fever, thirst, lung heat, wheezing and coughing, stomach fire, toothache, etc. The forged one can be used externally and can promote tissue regeneration and heal sores.

Light industry

Gypsum mold

When semi-hydrated gypsum hardens, it releases heat and increases in volume by about 1%. Due to this characteristic, it can be used to produce various gypsum parts for casting. The plastic gypsum slurry can be well filled into various parts, leaving clear and precise marks. When used as a mold for making ceramics, the gypsum mold can strongly absorb the moisture in the ceramic embryo, so that the ceramic body can obtain high strength during molding.

Example: Ceramic molds (gypsum itself can also be fired into ceramics), sculptures and other small sculptures, decorative floral decorations and various decorative relief molds, etc.

Papermaking

Gypsum has a stable volume, white color (the whiteness of gypsum exceeds that of all other fillers used for papermaking, such as kaolin, calcium carbonate and talcum powder), soft texture, and can be ground into fine powder to produce dense and high-quality paper.

Example: Used to make high-grade writing paper, typing paper, etc.

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/559.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap