Xingaonai

Xingaonai

Sand ratio refers to the percentage of sand mass in concrete to the total mass of concrete, that is: SP = sand amount S/(sand amount S+gravel amount G) × 100%. In the process of concrete preparation, sand ratio is a key parameter in concrete mix design, which determines the consistency of mortar and aggregate gradation in concrete. At the same time, the choice of sand ratio will directly affect the fluidity, cohesion, strength and durability of concrete.

Because in the concrete system, sand and cementitious material slurry form mortar to fill the pores between stones and wrap on their surface to play a lubricating role, and compared with stones, sand has a larger specific surface area, so the change of sand ratio will lead to changes in the total surface area of aggregates, and at the same time cause changes in aggregate porosity and relative content of coarse aggregates, which will affect the workability of concrete mixtures and the strength and durability of hardened concrete.

The mortar composed of sand and cement paste can play a lubricating role between coarse aggregates and reduce the friction between coarse aggregates, so the change of sand ratio has a direct impact on the fluidity of concrete. When the sand ratio is too small, the mortar in the concrete is not enough to fill the gaps between the coarse aggregates and wrap their surfaces, which will lead to poor fluidity of the concrete and affect its workability. As the sand ratio increases, the friction between the coarse aggregates decreases, and the fluidity of the concrete will increase. However, when the sand ratio exceeds a certain range, the total surface area of the aggregates increases, and the friction between the aggregates cannot be effectively reduced. The fluidity of the concrete will decrease with the increase of the sand ratio.

When the sand ratio is too small, the total surface area of the aggregates decreases, and its ability to absorb water on the surface is significantly reduced, which will make the cohesion and water retention of the concrete mixture worse, and it is easy to produce bleeding, segregation and slurry. As the sand ratio increases, the specific surface area of the aggregate increases, and the cohesiveness and water retention of the concrete mixture will be improved. However, when the sand ratio is too large and a certain amount of cement slurry is not enough to wrap the surface of the aggregate, the cohesiveness will deteriorate, and the concrete mixture will easily collapse and diverge.

If the sand ratio is too low, there will be a lack of sufficient mortar between the aggregates, which will not play a lubricating role, resulting in a weak interface and reducing the strength of the concrete. If the sand ratio is too high, the proportion of coarse aggregate in the concrete will increase, which will also reduce the strength of the concrete. Therefore, choosing the right sand ratio is crucial to balancing the strength and toughness of the concrete.

It seems that there is no direct relationship between the sand ratio and the durability of the concrete, because the sand ratio often affects the durability of the concrete after hardening by affecting the workability of the concrete mixture. If the sand ratio is too small, the water retention of concrete will decrease, making it difficult to vibrate and compact the concrete during the pouring process. After pouring, honeycombs and cavities are easily formed inside and on the inside of the formwork, and the surface is also prone to pockmarks, increasing the porosity inside the hardened concrete, reducing the impermeability of the concrete, and increasing the risk of erosion by moisture and harmful substances. If the sand ratio is too large, the concrete may be too dry and prone to shrinkage cracks. Therefore, a reasonable sand ratio can improve the durability of concrete.

The sand ratio also affects the economy of concrete, because if the sand ratio is too small, more materials are needed to make up for the defects, which will increase the cost of concrete; while if the sand ratio is too large, the quality of concrete may be unstable, requiring additional treatment and reinforcement, thereby increasing the cost. Therefore, choosing a suitable sand ratio can balance the cost and quality of concrete.

In summary, the change of sand ratio has both the filling effect of changing the voids of aggregates and the effect of changing the specific surface area of aggregates. Too high or too low a sand ratio may lead to a decrease in the working performance of concrete. Only a moderate sand ratio can make concrete have good fluidity, plasticity and stability, and be easy to construct and pour. Therefore, the sand ratio is of great significance to the performance of concrete. In actual projects, the appropriate sand ratio should be selected based on comprehensive considerations such as design requirements, raw material characteristics, construction conditions and engineering requirements to ensure that the concrete has good performance and economic benefits.

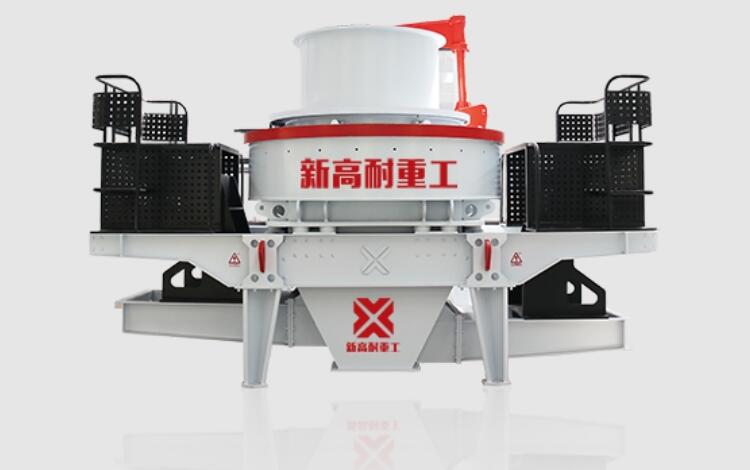

XinGaoNai Zhong Gong has strong technical strength and market competitiveness. Its projects are spread all over the world in cement building materials, sand and gravel aggregates, mining crushing and grinding and many other fields. It not only has a full set of sand and gravel production line equipment, but also can provide concrete mixing and supporting equipment for concrete production companies. In terms of equipment quality, we strictly control every production link to ensure that every equipment meets high standards, which can provide strong guarantees for the long-term development of customers and allow users to easily enjoy more comprehensive, more environmentally friendly, more efficient and more intelligent green recycling building materials overall solutions and services. Choose Xin Gao Nai Zhong Gong, you will get first-class sand and gravel production line equipment, concrete mixing equipment, as well as a full range of technical support and services!

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/535.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap