xgncrusher

xgncrusher

Graphite ore refers to a naturally occurring carbon ore, which is a carbonaceous non-metallic mineral. It usually exists in metamorphic rocks. Its symbiotic minerals are complex and are mainly accompanied by impurity minerals such as feldspar, quartz, and biotite. Graphite ore beneficiation As an indispensable part of the graphite industry chain, technology has various beneficiation methods. Purified graphite can be used in many fields such as optics, energy, aerospace, environment, and new materials.

3 types

The process characteristics of graphite mainly depend on its crystal form. According to the different crystal forms, natural graphite is usually divided into three categories in industry: dense crystalline graphite (lumpy graphite), cryptocrystalline graphite (earth graphite) and flake graphite. , these three types of graphite ores differ in mineralogy, morphology, carbon content and purity.

Lump graphite is relatively rare in nature and is the most valuable graphite ore. It has the best crystallization state, but its plasticity and slipperiness are not as good as flake graphite;

Earthy graphite has extremely fine particle size, high impurity content, the worst crystallization state, poor floatability, and is more complicated to utilize. In addition to crushing and grinding before flotation, gravity separation may also be required for pre-selection, but its The raw ore grade is higher;

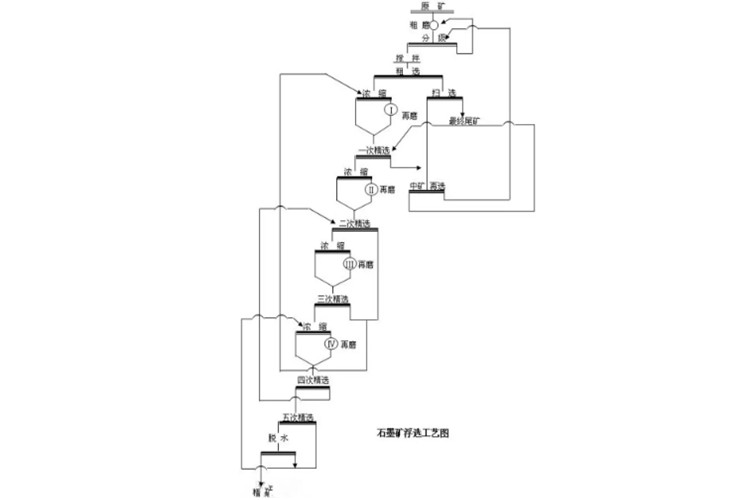

Flake graphite is one of the most floatable ores in nature. Although the grade of raw ore is not high, high-grade graphite concentrate can be obtained after multiple grinding and multiple separations. This type of ore has excellent floatability, lubrication and Its stability and plasticity are better than other types of graphite, so its industrial application value is the greatest.

Since natural graphite ore often contains a variety of impurities, it is necessary to improve its purity and application value through beneficiation processes. Common graphite beneficiation methods include flotation separation, gravity separation, acid leaching, heat treatment, electrostatic separation and combination Ore separation methods, among which gravity separation, flotation and electro-separation are widely used in graphite production.

There are various types of graphite with different structural characteristics, so the applicable mineral processing plans are naturally also different. For example: flake graphite has good floatability, so flotation is mostly used for separation. For graphite ore with a variety of gangues, a combined gravity separation and flotation process can be used.

In addition, the specific type and quality of graphite ore have an important impact on its suitability for various industrial applications. In actual production, each industrial sector also has its own requirements for the purity of graphite, so relative graphite must be used before use. Mineral beneficiation process to purify.

Commonly used equipment

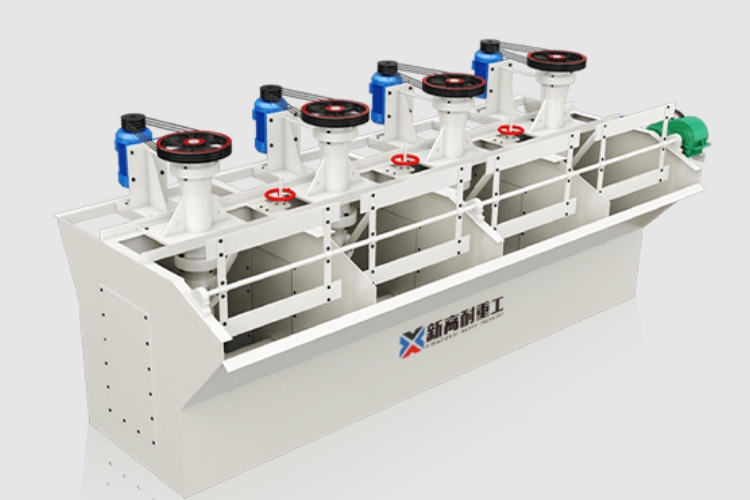

The hardness of graphite ore is generally medium hard or medium hard to soft. Generally, jaw crushers are used for coarse crushing, and cone crushers or hammer crushers are used for medium and fine crushing. Wet ball mills and grid-type ball mills are used for grinding; flotation Commonly used JJF type, XCF type, XJB type flotation machines; commonly used hydrocyclones or belt filter presses for mineral processing and dehydration.

It should be noted that when graphite is beneficiated, it is required to have a high concentrate grade and to protect the crystal structure of graphite as much as possible. Therefore, considering that the large-diameter mill has a stronger throwing effect and a greater impact on the graphite ore , it is easier to destroy the flake state of graphite. In on-site production, ball mills with a diameter of less than 2.7m are generally used, and a multi-stage regrinding and reselection process is used to protect the large graphite flakes from damage.

From industrial manufacturing to aerospace, from new energy technology to modern communications, graphite plays a key role. Therefore, it is crucial to extract high-purity graphite through the beneficiation process to ensure the quality of graphite products. Xingao Heavy Tools is equipped with advanced ore crushing and grinding equipment and technology. It can provide you with graphite beneficiation test analysis, select appropriate beneficiation plans and equipment, and produce a series of carefully designed processes such as crushing, grinding, and flotation. High-quality graphite that meets market demand, and maximizes the recovery of graphite components in ores, reduces the waste of resources, and helps you achieve a win-win situation of economic and social benefits. If you have relevant needs, please leave a message for consultation!

Author: Xingaonai

Reprint address: https://www.xgncrusher.com/Industralnews/141.html

Copyright © 2016-2030 Xingaonai Group All Rights Reserved. Xingaonai Sitemap