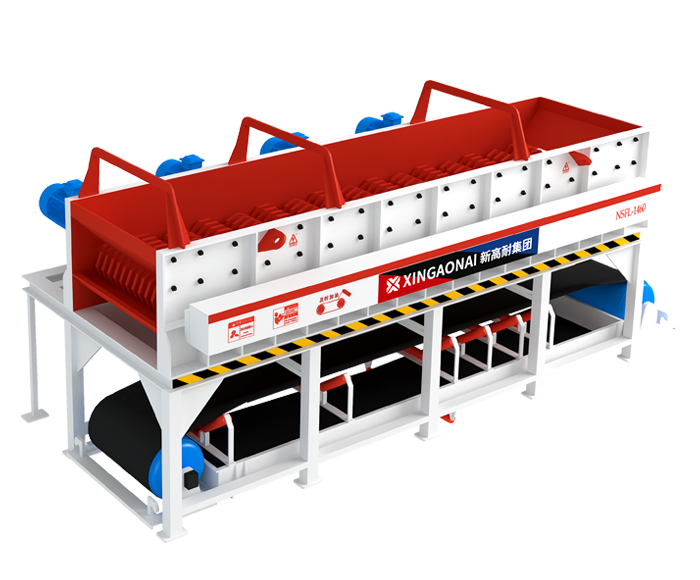

Applicable materials

Mud and gravel separator, also called multi-stage linkage roller screen, is suitable for coarse and fine separation of various materials that are difficult to separate, such as mud, soil, gravel, construction waste, etc.

Scope of application

Mud and gravel separators are widely used in the separation and screening of different types of mixtures in mining, building materials, chemical industry, sand and gravel plants and other fields.

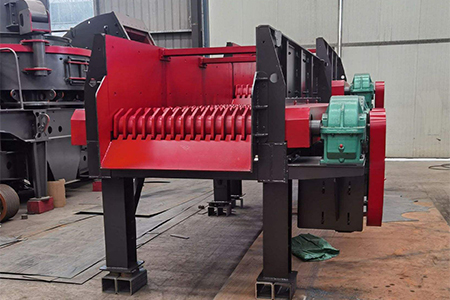

Internal Structure

It is mainly composed of boxes, lining plates, discs, transmission shafts, speed regulating motors, motor bases, chain sprockets, brackets and other structures.