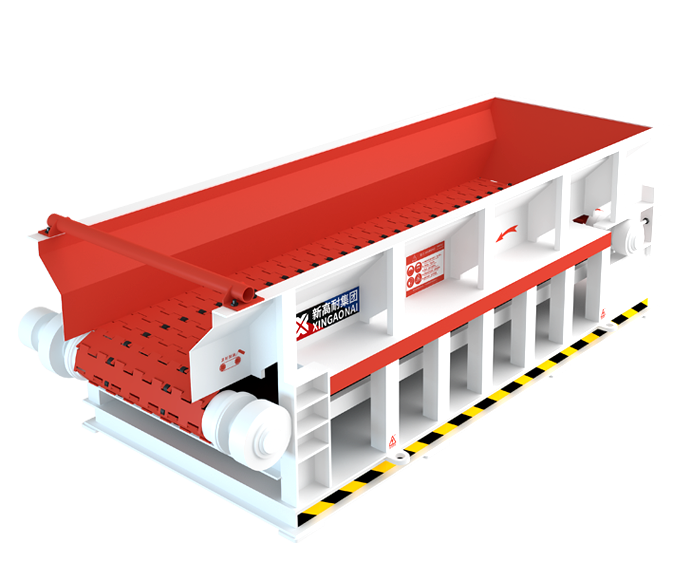

1、Efficient and durable

The equipment adopts standard tank chain transmission, which has large pulling force and high efficiency; The carrier plate is welded with high wear-resistant alloy steel plate, which is stronger and more durable.

2、Wide application

It can convey high-temperature materials below 400 degrees Celsius; the conveying angle can be horizontal or inclined to meet the different conveying tasks of various materials,and it has strong environmental adaptability and is not afraid of harsh working conditions.

3、Stable operation

Driven by a frequency conversion motor, it starts smoothly and feeds evenly; tTighten the buffer design of the device to effectively reduce the impact of the equipment vibration; the material trough is connected by an arc-shaped lap joint, which can effectively prevent material leakage.

4、Reasonable design

The structure of the traction chain is reasonable, which effectively improves the impact load capacity and can withstand large silo pressure;the main axis and sprocket wheels are connected with swelling sleeves and no keys, which is not only good, but also easy to disassemble and convenient maintenance.