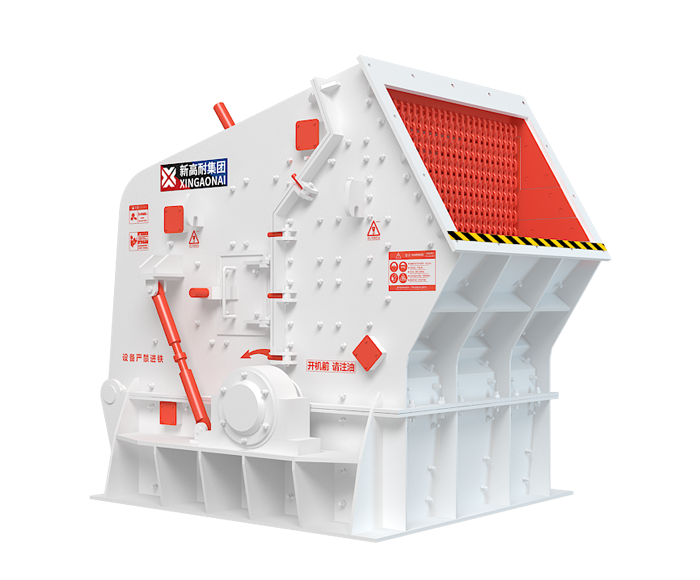

1、HIGH QUALITY MATERIAL

High chromium castings are used as the material of the hammer, and a locking device is used at the junction of the hammer and the rotor to avoid the risk of the hammer breaking and falling off during high-strength work. The hammer can be turned over after it is worn out.

2、Environmentally friendly

The PF series adopts a specially designed heavy-duty rotor structure with extremely high rotational inertia and hammer impact crushing force. It is equipped with a low-power motor, and the equipment consumes low power, is energy-saving and environmentally friendly.

3、REASONABLE STRUCTURE

The fuselage adopts finite element computer-aided design, high-strength hot-rolled alloy steel plate, and the weight of the equipment is reduced, while ensuring the long-term stability of the machine during high-strength work.

4、Cut costs

in aggregate production and solid waste treatment, PF series impact crusher changes three-stage crushing to two-stage crushing, which greatly reduces the investment of equipment.

5、GRANULARITY CONTROLLABLE

The gap between the impact plate and the hammer can be adjusted quickly, which is convenient to control the discharging grain shape and the product grain shape is round and the stone powder content is low.

6、Reduce failures

Equipped with a hydraulic lifting device, which can quickly replace the vulnerable parts such as the hammer, which greatly reduces the downtime and maintenance time of the production line.