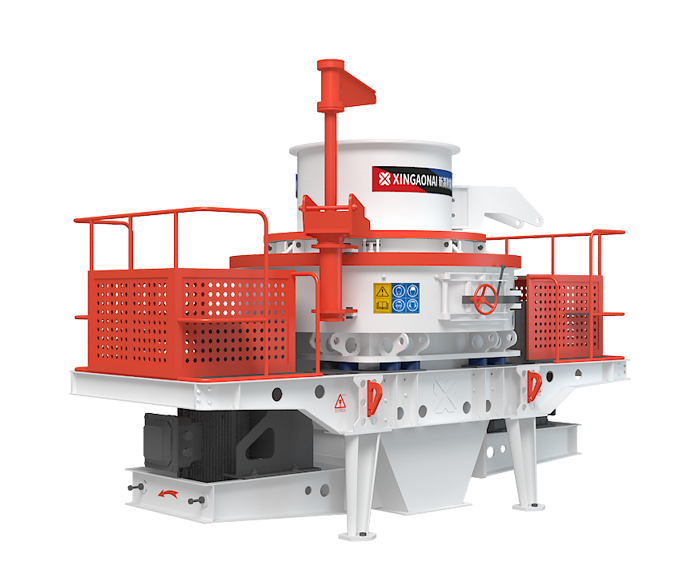

1、Feeding method flexible aiverse

By adjusting the hopper feeding device, it is easy to achieve the conversion between the two modes of "falling feeding + centre feeding" and "full centre feeding". Adjusting the angle of the distribution plate can avoid the direct impact of the material on the impeller and reduce the abnormal wear of the impeller.

2、Large throughput

The design of the large discharge port makes the material unloading more smoothly, which effectively prevents material blockage, avoids abnormal damage to the equipment, and improves the crushing efficiency.

3、Hydraulic device maintenance is convenient

Advanced hydraulic opening and hanging devices can easily hang into the hopper, hanging plates, impeller, bearings, etc., effectively reduce the difficulty of daily maintenance and maintenance of the equipment, and save labor time.

4、Four -mouth impeller cost reduction and efficiency

The new four-port impeller design, compared with the crushing of the same material with the three-port impeller, the crushing efficiency is increased by about 20%, and the service life of the impeller is extended by 30~150%.

5、High quality vulnerable parts are wear-resistant and durable

The transmission part and core component are reasonable, extend the life span of easy loss of the loss, effectively reduce the maintenance time of the shutdown and the wear of the loss of the loss,and the Zhouhu plate can be used up and down after all grounding, the utilization rate is high, and the operating cost is low.