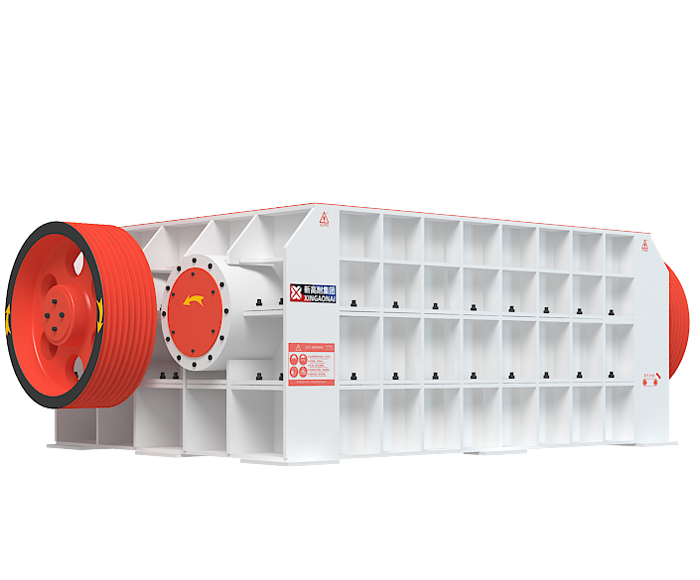

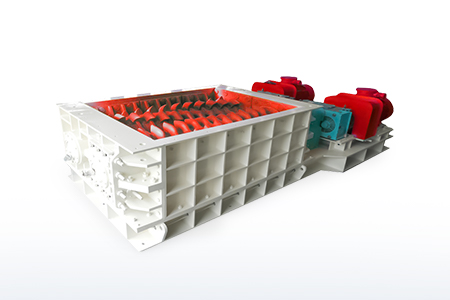

1、High -quality material selection crushing rate high

Broken teeth are cast with Bashi grinding alloy, the casting and thermal external process are advanced, with high strength, toughness and abrasion resistance. The service life is 2-3 times that of the industry's general high manganese steel and alloy steel; two sets of independent driving devices, the two broken rollers can work independently, and in actual production, the working system can be changed according to the amount of feeding, use stand -alone work when the feed is small, dual -machine work when the feed is big, high energy saving efficiency.

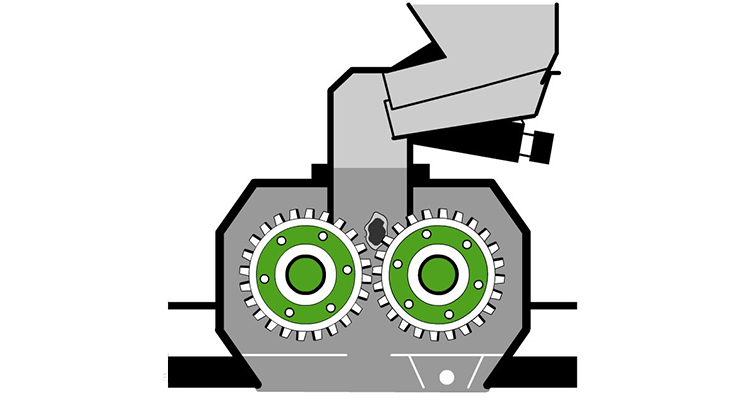

2、Excellent material type

The shape of the roller surface is divided into thick and fine tooth rollers, which can be adjusted according to the size required by the material; the principle of dual crushing of shear and stretching, dual motors slowly drive through hard tooth surface grinding tooth reducer, high stability and uniform granularity.

3、Various configuration cost -effective

It has a variety of crushing tooth types such as living tooth type, stuck type, tooth ring type, tooth plate, and whole roller type. It can be optimized for customers according to the working conditions and tailor -made; It has a variety of crushing tooth layout methods such as large spiral, double spiral, multi -spiral and straight lines, and has high crushing efficiency; it has a variety of walking structures of fixed, silk -type, hydraulic and electric types, which is convenient for maintenance and maintenance.

4、Design reasonable and intelligent environmental protection

Special structure design of the main axis, high stability; crushing roller sweeping device, broken wet sticky material non -stick roller; Overload protection device, intelligent control, lubricating system, convenient operation, stable operation; the crushing cavity adopts the overall box structure, has good closedability, and has a high degree of cleanliness, and effectively solve the phenomenon of bearing positioning of the split box structure and the phenomenon of the axis bearing.